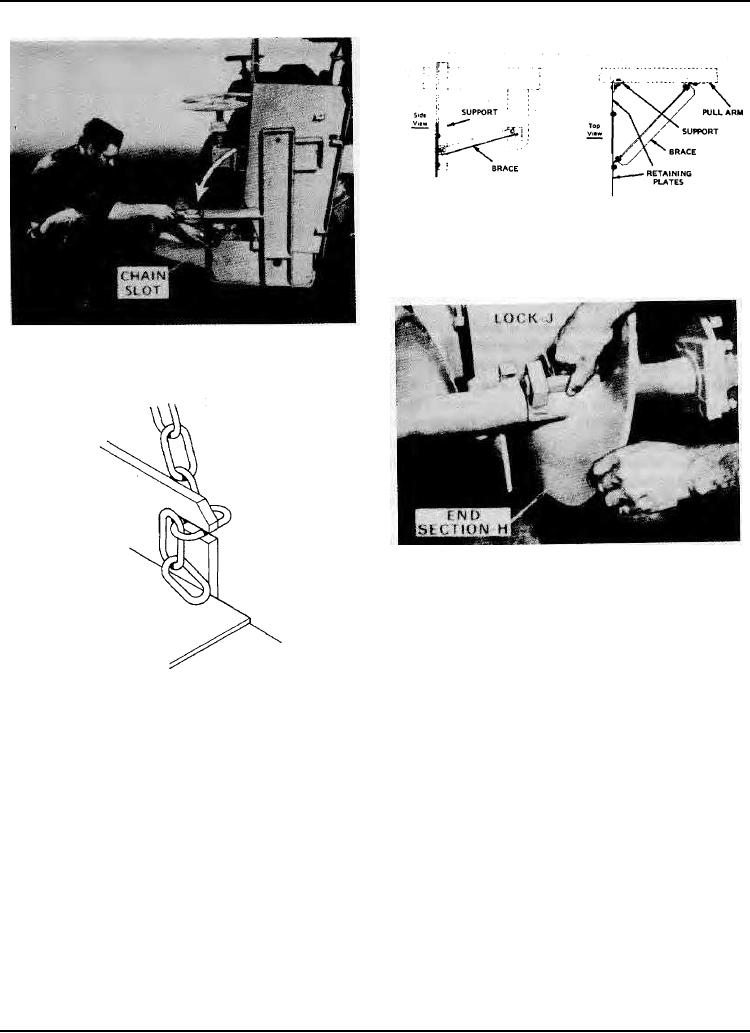

Typical 36" Retaining Plate Arrangement

Figure 16

Swinging Side Plate to Vertical Position

& Anchoring to Permit Material Bleeding

Figure 14

Disengaging Coupling to Stop Screw End Section

Figure 17

ceeds two, an extra brace is added. (See Figure 16).

Method of Attaching Chain for Bleeding

Cut-off Shoes (Refer to Figure 18)

Figure 15

Standard cut-off shoes which fit the paver

Bevel Guide Plates (Refer to Figure 12)

extensions reduce the paving width in varying

Bevel guide plates can be bolted to the side plates

amounts in 112" increments, down to the minimum of

in order to produce a beveled edge on the mat as the

10 ft. They slide under the side plates and are bolted

material is deposited. The degree of bevel is 450. The

in place. Bolt holes are spaced 1 /2" apart.

bevel depths available are 1/2" and 3".

(1) To install cut-off shoe, block up screed to

Retaining Plates

shoeheight.

Material retaining plates must be used ahead of

(2) Raise side plate and slide cut-off shoe "G" under

extended screw conveyors whenever the mat

screed as much as required for desired mat width

extension exceeds 2 ft. These plates prevent the

reduction. (See Figure 19)

forward spread of material so that the screws are

(3) Bolt cut-off shoe to side plate. (Shoe fits either

handling a uniform depth all the way out to the ends

end of screed.)

(See Section 6, Figures 10 & 11). When up to 4 ft. of

(4) Release lock (J) on spreader screw to allow tip

extension is added to one end of the screed a

screw section (H) to become idle. To prevent material

retaining plate support angle is attached to the screed

from being fed onto the top of the cut-off shoe and

pull arm and when the number of plates ex-

spilling onto the road base, fashion pieces

Page 58