justment for the mat texture while paving. Never

lower strike-offs below screed bottom. Important!

Always make strike-off adjustments when screed

and asphalt are hot. If the asphalt is cold,

adjusting bolts and brackets will bend before the

strike-off moves and the entire adjustment

assembly is damaged.

4. Whenever strike-offs are to be re-adjusted, it is

best to lower both sides, then use the top adjusting nut

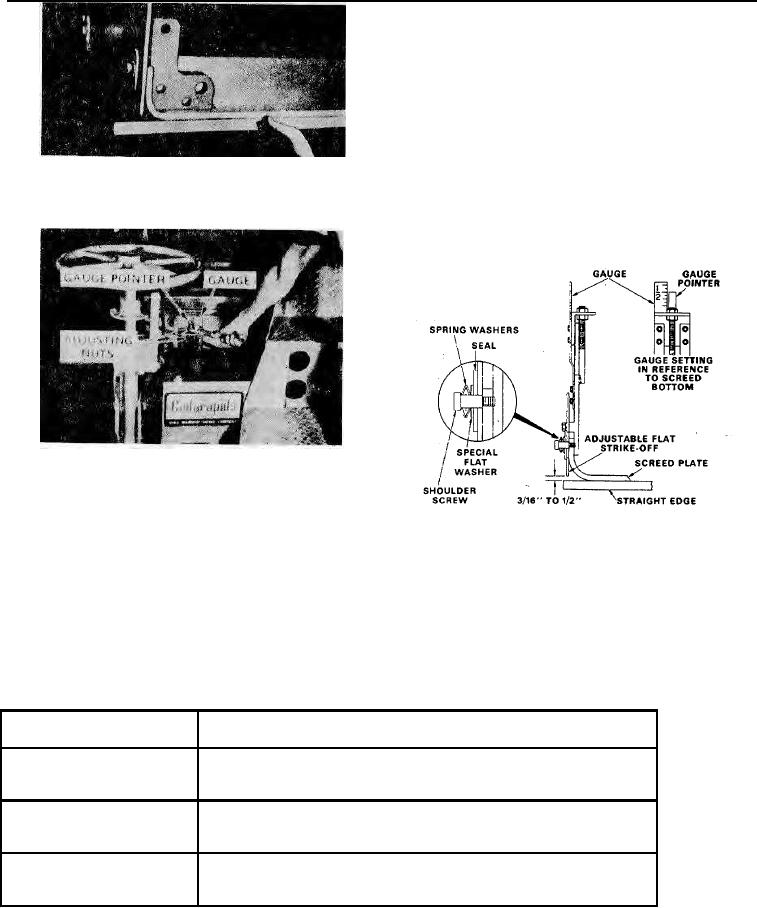

Checking Height of Flat Strike-off

at each of the four adjustment points to pull the strike-

Figure 23

offs up to the desired gauge readings. This is a

uniform movement of the strike-offs and

Adjusting Height of Strike-off

Figure 24

ZEROING AND ADJUSTING STRIKE-OFFS

Cross-section - Flat Strike-off Assembly

1. After strike-offs are properly assembled to

Figure 25

sereed.

lower strike-offs until flush with screed

bottom. Use the template straight edge to check

position of strike-offs. See Figure 23.

2. Then, adjust gauges to "0" setting with gauge

pointers.

3.

Raise strike-offs above screed bottom

according to the chart. (Shown below.) Make the final

ad-

Height of

Flat Strike-off

Characteristics of Asphalt

"+1/16"

Standard (Normal Mat Conditions)

1/4"

Aggregate Size; Sand to 1" Minus Aggregate

- 0"

Mat Thickness: 1" to Maximum Thickness

Alternate (Fines Materials with Thin Mat)

3/16" + 1/16"

Aggregate Size: Fines to 1/4" minus sand

Mat Thickness: Minimum 1/2" to 1" mat

3/8" + 1/8"

**Alternate (Coarse Materials with Thick Mat)

3/8"

*Aggregate Size: 1" minus 1" maximum Recommended

__- 1/16"

Mat Thickness: 2" to maximum thickness

*Pavers have laid top size material of 3" minus, however accelerated wear can be expected.

**Only if tearing due to flats in aggregate. With flat plate strike-off it is possible to raise to 1",there-

fore, no strike-off effect.

Page 61