ing edge of the screed is not in contact with the mat

being laid.

Vibrators connected to the screed bottom support

will not be operating efficiently as the full screed plate

width is not being utilized. Mat appearance and

texture will change with only slight movement of the

screed adjusting hand wheels.

f. Loose or worn screed.

7. Correct pull point settings become a matter of

experience. Locating center line of pull points 14 1/4"

from the ground has proven satisfactory for most

paving jobs. Settings listed will normally cover the

necessary adjustments when laying both stable and

unstable mixes. The softer and more unstable the

material, the more important it becomes to have the

screed flat with the mat.

NOTE: Unstable mixes can be caused

by too much asphalt in the mix, poor

poor

quality

asphalt,

excessive temperature, moisture in the

material and insufficient dust.

IMPORTANT: Both pull points must be

located equal distance from the ground.

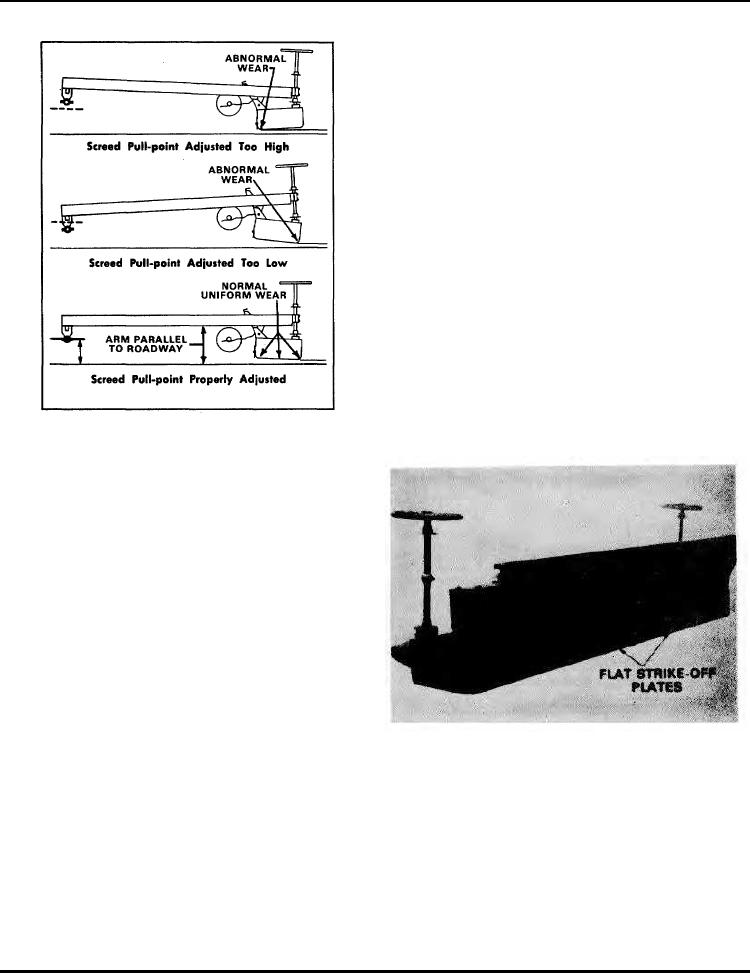

Effect of Pull-point Height on Screed Wear

Figure 21

erational difficulties will be encountered.

a. Premature wear on the trailing edge of the the

screed.

b. A tendency for the screed to climb each time the

paver starts with normal hand wheel setting. Poor

control of mat thickness will exist and good transverse

joints will be difficult' to make.

c. Possible tearing of the mat because of excessive

ironing effect of the screed.

d. Loose or worn screed.

6. When the pull points are too high and the front of

the screed is tilted down, in order to maintain the

correct mat thickness, the following wear and

operational difficulties will be encountered.

a. Premature wear on the leading edge of screed and

Flat Strike-off Installed on Screed

possibly deformation of the strike-offs because of the

Figure 22

excessive pressures exerted against it when operating

in this manner.

STRIKE-OFF

b. Bumpy, wavy road caused by the screed riding on

The strike-off located ahead of the screed plate, is

its leading edge.

a metering, pre-compactor, and pre-screeding device,

c. Tendency for screed to dip each time the paver

that when properly positioned provides the exact

starts with normal hand wheel setting.

amount of material to the screed. It also absorbs wear

d. Tearing the mat, caused by the "digging in" action

which would otherwise take place on the leading edge

of screed.

of the screed bottom. If this strike-off is not properly

e. Loss of compaction will result as the trail-

adjusted and maintained, it can cause operational

difficulties.

Page 60