ing job is to be started, or when an extensive

thickness change is to be made on a job, the operator

can adjust the handwheels to the reference marks and

start-off very close to the mat thickness desired, if he

has recorded reference close to the new requirement.

Without a reference he must guess at the setting and

make corrections on the first several feet of the new

mat. Eventually an operator's reference record will

cover most of the common mat thicknesses and types

of material used

Change of material specifications will usually

cause a different screed behavior and a different

handwheel setting, even though the mat thickness is a

common one.

To obtain a smooth mat, the screed adjustment

controls should be gradually changed, one notch at a

time, and the screed should travel a few feet before

an additional adjustment is made. This will allow

the screed the proper distance of travel required to

seek the new level of operation.

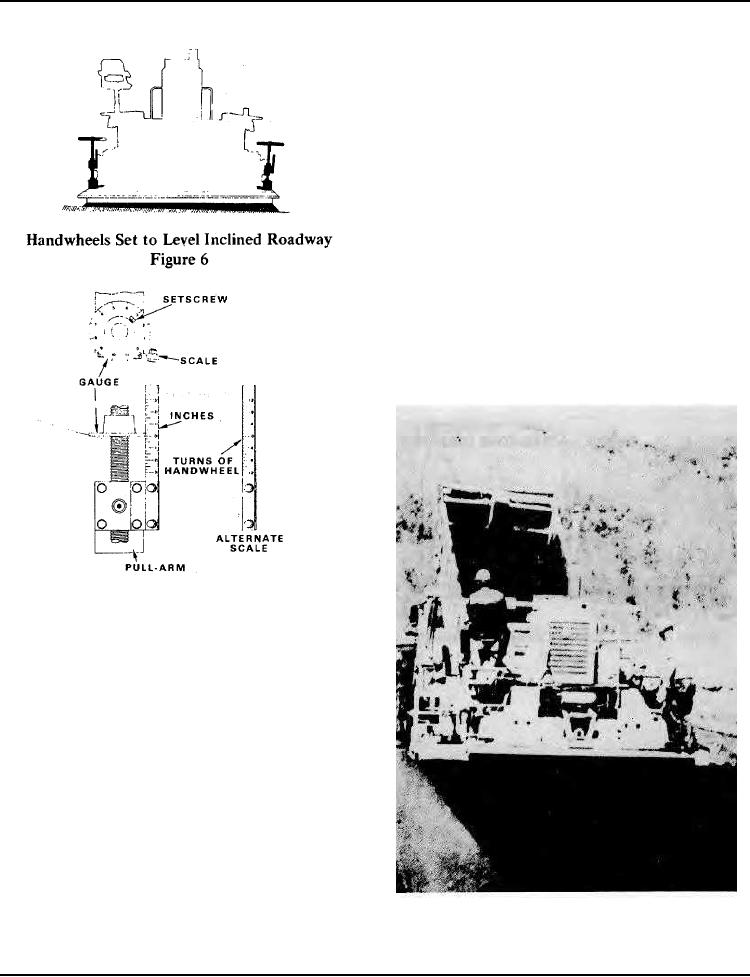

Handwheels Set to Level Inclined Roadway

Figure 6

The scale is graduated vertically from a central

zero marking. The graduations may be in inches, with

increments of 1/4", 3" each way from the zero, so

that the total range is 6". Or the graduations may be

in turns of the handwheel, with increments of 1 turn,

12 turns each way from zero, so that the total range is

24 turns.

The disc-like gauge which is attached to the

handwheel screw has 12 equally space markings

which can be indexed from the edge of the vertical

scale to show the division of 1 turn.

The scale reading is taken by holding a small

straight edge upward against the bottom of the gauge

disc and across the scale face.

When an operator has established the best hand

wheel setting for paving a specific thickness with a

specific material, he will zero the two gauge and scale

readings then tighten the gauge setscrews. He then

Screed Man Making Handwheel Adjustment

makes a record of the conditions and gauge settings

Figure 8

for future reference. Whenever a new pav-

Page 55