TM 5-3895-373-34

A.

REMOVE - Continued.

2.

REMOVE SCREED TRAVEL LOCK VALVE.

Hydraulic

oil

can

be

moderately

flammable and can be an irritant to the

skin, eyes, and respiratory system.

Avoid

prolonged

exposure.

Eye

protection and rubber gloves must be

worn when working with hydraulic oil.

a.

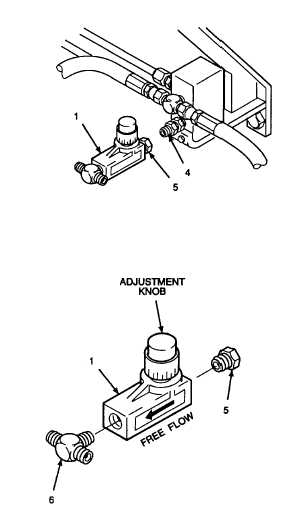

Hold pipe nipple (4) with a wrench. Remove

screed travel lock valve (1) by removing pipe

reducer (5). Drain any excess hydraulic oil into

drip pan. Cap nipple with protective cap.

b.

Dispose of hydraulic oil in drip pan in accordance

with local procedures.

c.

Remove pipe reducer (5) and tee (6) from

screed travel lock valve (1).

B.

INSTALL.

1.

INSTALL SCREED TRAVEL LOCK VALVE.

a.

Use cleaning cloth to wipe residue from threads

of pipe reducer (5), tee (6), and pipe nipple (4).

Pipe sealant can cause eye damage or

skin irritation. Wash after skin contact.

Wear

safety

goggles/glasses

when

using. Avoid contact with eyes or skin.

If sealant contacts eyes, flush eyes with

water

and

get

immediate

medical

attention.

Ensure fittings are installed correctly into

screed travel lock valve. If fittings are

installed incorrectly into screed travel

lock valve, screed. may drop suddenly,

causing serious injury or death.

b.

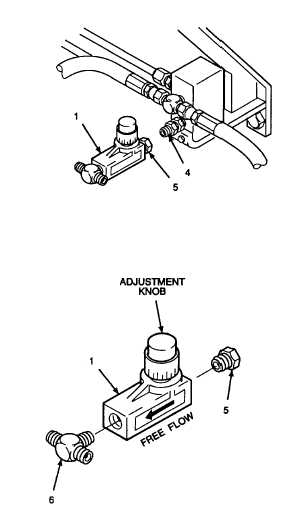

Apply pipe sealant to male threads of pipe

reducer (5) and install reducer onto screed travel

lock valve (1) at end closest to adjustment knob.

Tighten reducer.

c.

Apply pipe sealant to pipe threads of tee (6) and

install tee onto screed travel lock valve (1) at end

closest to arrow (free flow end). Tighten tee so

that tee is aligned as shown in illustration

d.

Apply pipe sealant to threads of pipe nipple (4).

e.

Install screed travel lock valve (1) onto pipe

nipple (4). Tighten pipe reducer (5) and position

screed travel lock valve with adjustment knob on

top

GO TO NEXT PAGE

2-797