TM 5-3895-373-34

2.57

REPLACE SCREED TRAVEL LOCK VALVE - Continued

A.

REMOVE.

1.

DISCONNECT HYDRAULIC HOSES.

Thoroughly clean hydraulic hoses and

fittings before disconnecting. Always

plug or cap off disconnected fittings to

prevent

intrusion

of

contaminants.

Failure to properly clean and cap off

connectors

may

result

in

hydraulic

system contamination and equipment

damage.

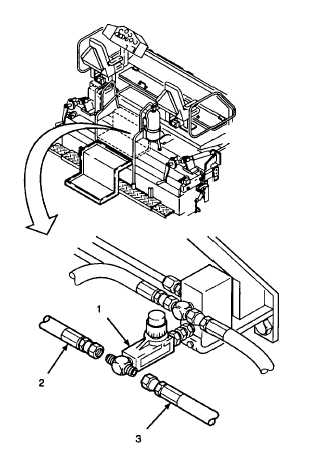

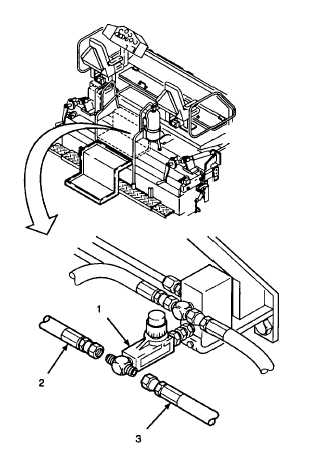

a.

Wipe all dirt and dust from hydraulic fittings

around screed travel lock valve (1) with a

cleaning cloth. Tag hoses (2 and 3).

Hydraulic

oil

under

pressure

can

penetrate skin or damage eyes. Severe

injury or loss of limb may result from

contact with high pressure fluid leaks.

Wear

safety

goggles/glasses

at

all

times. If hydraulic oil enters skin or

eyes, get immediate medical attention.

Severe injury can result from contact

with high pressure oil.

b.

Shield screed travel lock valve (1) with layered

machinery wiping towels.

c.

Hold drip pan under screed travel lock valve (1)

and slowly loosen hoses (2 and 3) to relieve

pressure from the hydraulic system. When the

pressure is relieved, disconnect and plug hoses.

GO TO NEXT PAGE

2-796