TM 5-3895-373-34

2.49

REPAIR AUGER/CONVEYOR, VALVE AND CYLINDER, AND TOW POINT FLOW DIVIDERS - Continued.

B.

CLEAN Continued.

2.

CLEAN FASTENER THREADS.

WARNING

Thread locking compound solvent

can cause eye damage. Wear safety

goggles/glasses when using. Avoid

contact with eyes. If solvent contacts

eyes, flush eyes with water and get

immediate medical attention.

a.

Clean all hex head cap screws with thread

locking compound solvent.

b.

Wipe hex head cap screws dry with a cleaning

cloth.

c.

Wipe hydraulic fittings with a cleaning cloth to

remove hydraulic fitting sealant residue.

C.

INSPECT.

1.

INSPECT

END

PLATES,

CASES,

AND

SPACER PLATE FOR WEAR.

a.

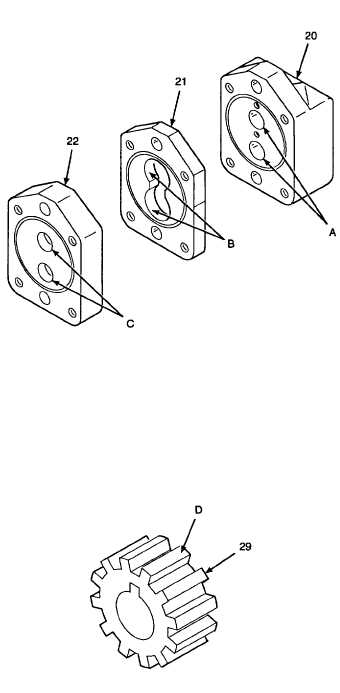

Visually inspect end plates (20), surface A,

cases (21), surface B, and spacer plate (22),

surface C, for wear from gear movement.

b.

Replace either end plate (20), case (21), or

spacer plate (22) if excessive wear is detected.

2.

INSPECT GEARS FOR DAMAGE.

a.

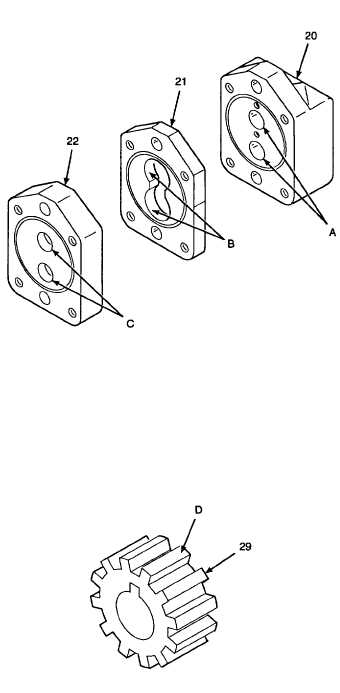

Visually inspect gears (29), surface D, for

damaged or chipped teeth.

b.

If auger/conveyor flow divider or valve and

cylinder flow divider gears are being inspected,

replace gear if damaged or chipped teeth are

detected.

c.

If tow point flow divider gear is being inspected,

replace entire flow divider if damaged or chipped

teeth are detected.

GO TO NEXT PAGE

2-668