TM 5-3895-373-34

2.32

REPLACE/REPAIR PROPULSION MOTOR - Continued.

F.

ADJUST.

1.

CONNECT

PROPULSION

MOTOR

TO

HYDRAULIC SYSTEMS TEST AND REPAIR

TOOL

OUTFIT

(HSTRU)

AND

SET

PROPULSION

MOTOR

OPERATIONAL

PARAMETERS. REFER TO TM 9-4940-468-14

AND TABLE BELOW.

MOTOR

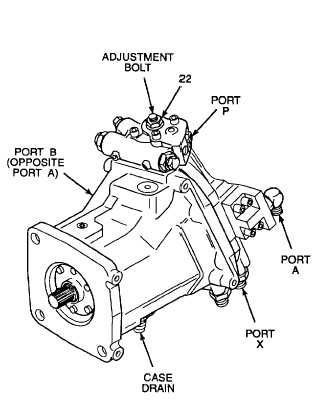

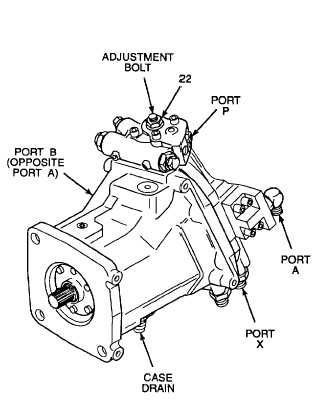

CONNECT

REQUIRED

PORT

PORT TO

FLOW/PRESSURE

X

Variable

120 to 220 psi

source

(827,37 to 1516,86 kPa)

P

Constant

220 psi (1516,86 kPa) constant

source

T

Tank return

N/A

A

Pump input

26.5 1.5 gpm (98 :5,7 l/min)

at 3000 psi (20 685 kPa)

B

Pump output

23.5 1.5 gpm

(89 5,7 l/min), minimum

CASE

Tank return

3.0 gpm (11 l/min) or less

DRAIN

2.

WITH A CONTINUOUS INPUT FLOW AT

PROPULSION MOTOR PORT A OF 26.5 1.5

gpm (98 5,7 l/min) AT 3000 PSI (20 685 kPa),

MOTOR ROTATION SHOULD BE 1962.75 RPM

WITH 120 PSI (827,37 kPa) PROVIDED AT

VARIABLE

PRESSURE

SOURCE

X

AND

3925.5 RPM AT 220 PSI (1516,86 kPa)

PROVIDED

AT

VARIABLE

PRESSURE

SOURCE X.

3.

LOOSEN NUT (22) AND TURN ADJUSTMENT

BOLT AS REQUIRED TO ATTAIN CORRECT

RPM

AT

DESIGNATED

PRESSURE

AND

FLOW. TIGHTEN NUT TO 37 Ib-ft (50 N•m).

GO TO NEXT PAGE

2-466