TM 5-3895-373-34

E.

ASSEMBLE - Continued.

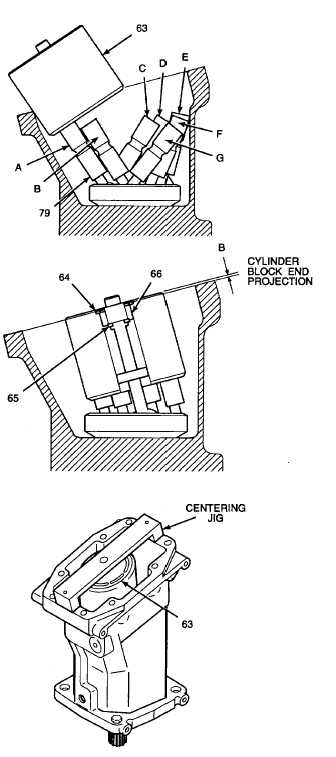

NOTE

Pistons A and B are inserted to the left while

pistons C and D, E and F, and G are laying to

the right of the mechanical drive housing.

d.

Install cylinder block at an angle, fitting

pistons (79) one at a time into cylinder

block (63) as shown.

e.

After pistons A and B are inserted in

cylinder block (63), insert pistons C and D,

moving the pistons from right to left. Install

pistons E, F, and G while gradually lowering

the cylinder block.

f.

Seat cylinder block (63) down firmly on

pistons (79).

Use care when installing snap and retaining

rings. Snap and retaining rings are under

spring tension and can act as projectiles

when released and could cause severe eye

injury.

NOTE

If shims (65) were removed from cylinder

block (63) at disassembly, install them at this

time.

g.

Use retaining ring pliers and install shims

(65), ring spacer (66), and retaining ring

(64) into cylinder block (63) retaining ring

groove.

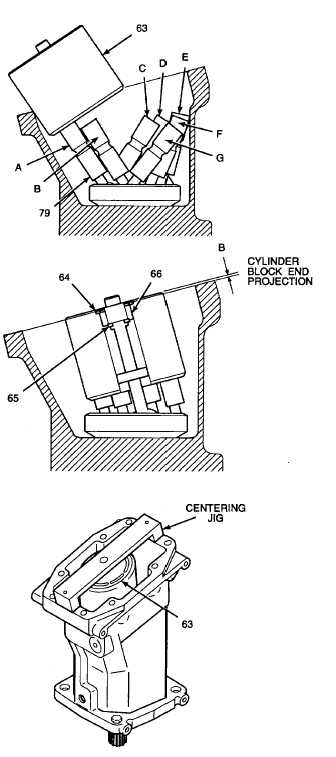

h.

Center cylinder block (63) in mechanical

drive housing with a centering jig.

i.

Use a depth gage and measure distance

(B)

cylinder

block

end

projects

from

mechanical drive housing.

j.

Refer to measurement (A) taken in step 2.d

for port plate depth in port plate housing.

k.

Combined cylinder block end projection (B)

and port plate depth (A) must not exceed

0.007 in. (0,02 mm) total.

l.

If cylinder block projection exceeds 0.007

in. (0,02 mm), subtract the difference from

combined measurement. This will give the

required shim thickness as follows:

A - B = total - 0.007 in. (0,02 mm) =

total shim thickness

Total less 0.007 in. (0,02 mm) = shim

thickness required.

GO TO NEXT PAGE

2-457