TM 5-3895-373-34

D.

INSPECT.

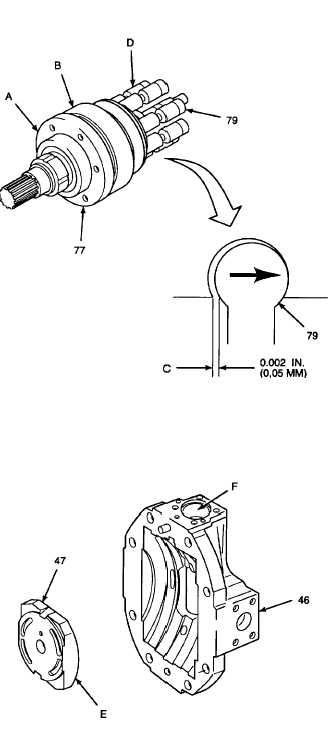

1.

INSPECT SHAFT ASSEMBLY FOR DAMAGED

BEARINGS AND EXCESSIVE WEAR.

a.

Manually turn bearings, A and B, on shaft

assembly (77).

b.

If bearings turn rough or do not spin freely,

replace shaft assembly (77).

c.

Use

a

thickness

gage

and

check

piston/socket end-play, dimension C, by

inserting end of thickness gage between

rounded end of each piston (79) where it

connects into shaft assembly (77).

d.

Measure amount of free play between

pistons (79) and shaft assembly (77) by

moving each piston back and forth in its

socket.

e.

Check each piston (79) in this manner.

f.

If end play, dimension C, exceeds 0.002 in.

(0,05 mm) in any piston (79) and socket,

replace shaft assembly (77).

g.

Inspect

piston

(79),

surfaces

D,

for

scratches.

h.

If surfaces of pistons (79) have scratches

that can be felt with a fingernail, replace

shaft assembly (77).

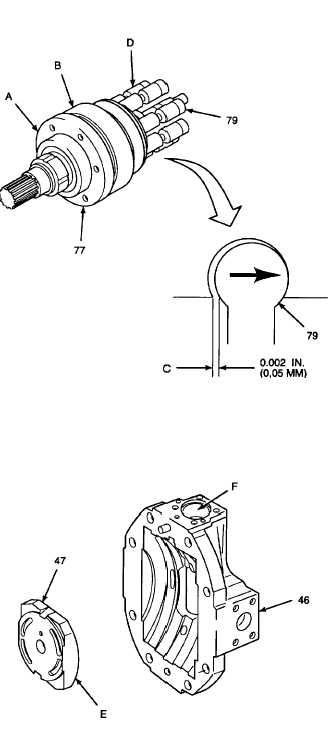

2.

INSPECT PORT PLATE AND PORT PLATE

HOUSING FOR DAMAGE AND EXCESSIVE

WEAR.

a.

Visually inspect port plate (47), surface E,

for scratches.

b.

Use emery cloth to remove any scratches

from port plate that can be felt with a

fingernail.

c.

Clean port plate (47) after polishing. Refer

to cleaning procedure.

d.

Replace port plate (47), and port plate

housing (46) if deep scratches cannot be

removed with emery cloth.

e.

Use a strong light and inspect port plate

housing (46) inner bore, surface F, for

discoloration and scratches that can be felt

with a fingernail.

GO TO NEXT PAGE

2-453