TM 5-3895-373-34

E.

ASSEMBLE.

1.

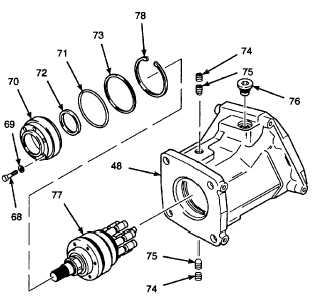

INSTALL SHAFT ASSEMBLY AND MOTOR

COVER INTO MECHANICAL DRIVE HOUSING.

a.

Install shaft assembly (77) into mechanical

drive housing (48). Lightly tap with plastic

hammer if necessary.

Use care when installing snap and

retaining rings. Snap and retaining

rings are under spring tension and

can act as projectiles when released

and could cause severe eye injury.

NOTE

Ensure retaining ring is seated in

retaining ring groove.

b.

Use retaining ring pliers and install retaining

ring

(78).

Ensure

retaining

ring

is

positioned to allow installation of socket

head cap screws (68).

Thread locking compound can cause

eye

damage.

Wear

safety

goggles/glasses when using. Avoid

contact with eyes. If compound

contacts eyes, flush eyes with water

and get immediate medical attention.

NOTE

Shaft assembly (77) must be seated

against retaining ring to allow set

screws to seat in groove of shaft

assembly.

c.

Coat threads of set screws (75 and 74) with

thread

locking

compound

(Item

14,

Appendix B).

d.

Install set screws (75 and 74). Use a hex

head driver socket (Item 89, Appendix D)

and tighten screws to 7 lb-ft (10 N•m).

e.

Install plug (76).

f.

Install shim (73) into mechanical drive

housing (48) against retaining ring (78).

g.

Lubricate o-ring (71) and seal ring (72) with

petrolatum.

h.

Install o-ring (71) into mechanical drive

housing (48) against shim (73).

i.

Use shaft seal installation tool and install

seal ring (72), sealing lip up, into motor

cover (70).

j.

Align screw holes on motor cover (70) with

screw holes on shaft assembly (77).

k.

Press motor cover (70) into mechanical

drive housing (48) by tapping with a plastic

hammer.

I.

Install seal rings (69) onto socket head cap

screws (68).

m.

Install socket head cap screws (68) into

motor cover (70). Use a hex head driver

socket (Item 90, Appendix D) and tighten

cap screws to 7 Ib-ft (10 N•m).

GO TO NEXT PAGE

2-455