TM 5-3895-373-34

2.25

REPAIR STARTER ASSEMBLY - Continued

B.

CLEAN.

1.

WIPE ALL PARTS WITH A CLEAN, LINT-FREE

CLOTH.

2.

PLACE

ALL

PARTS

ON

A

CLEAN

WORK

SURFACE FOR INSPECTION.

C.

INSPECT.

1.

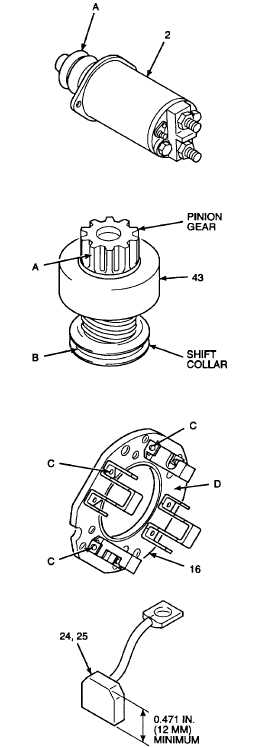

INSPECT SOLENOID (2) FOR CUT OR TORN

BOOT (SURFACE A). REPLACE SOLENOID IF

BOOT IS TORN OR CRACKED.

2.

INSPECT BENDIX COMPONENTS FOR DAMAGE

AND WEAR.

a.

Turn pinion gear manually on bendix (43).

b.

Check for rough turning and the ability of pinion

gear to turn in both directions.

c.

Inspect pinion gear surface A for broken teeth

and step wear.

d.

Inspect shift collar surface B for deep scoring

and damage.

e.

Replace bendix if pinion gear turns rough or in

both directions, pinion gear teeth are damaged

or worn, or shift collar is scored or damaged.

3.

INSPECT BRUSH HOLDER ASSEMBLY FOR

LOOSE

RIVETS

AND

CRACKED

OR

BROKEN

INSULATION. MEASURE BRUSHES.

a.

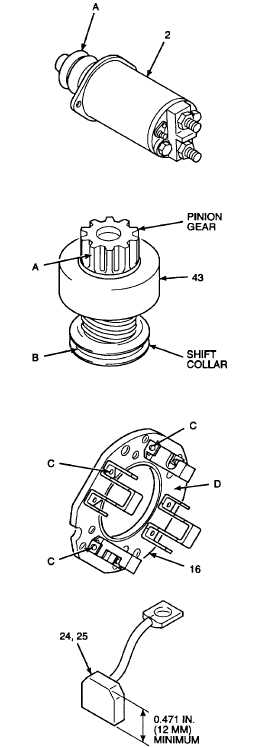

Inspect brush holder assembly (16) surface C for

loose riveted joints and surface D for cracked or

broken insulation.

b.

Replace brush holder assembly (16) if rivets are

loose or insulation is cracked or broken.

c.

Use an outside micrometer (Item 15, Appendix

D) to measure brush (24 and 25) length.

d.

Minimum allowable brush (24 and 25) length is

0.472 in. (12 mm). If any one brush length is

0.471 in. (12 mm) or less, replace all brushes.

GO TO NEXT PAGE:

2-342