TM 5-3895-373-34

2.22.

REPLACE/REPAIR FUEL TANK - Continued

B.

CLEAN - Continued.

Use caution when scraping gasket

material from water pump. Do not

scratch or gouge water pump sealing

surfaces

when

scraping

gasket

material.

Poor sealing and coolant leakage

may result from scratches or gouges

in water pump sealing surfaces.

2.

USE A PUTTY KNIFE TO SCRAPE GASKET

RESIDUE FROM BEARING BODY GASKET

SEALING SURFACES.

Compressed air used for cleaning

purposes will not exceed 30 psi (207

kPa). Use only with effective chip

guarding

and

personal

protective

equipment (goggles/face shield and

gloves).

Failure to take proper precautions

may result in severe injury or loss of

vision.

3.

USE 30 PSI (207 kPa) MAXIMUM COMPRESSED

AIR TO REMOVE ANY FOREIGN MATERIAL.

DRY WITH A CLEANING CLOTH.

C.

ASSEMBLE.

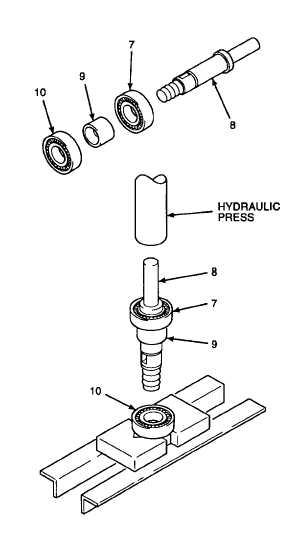

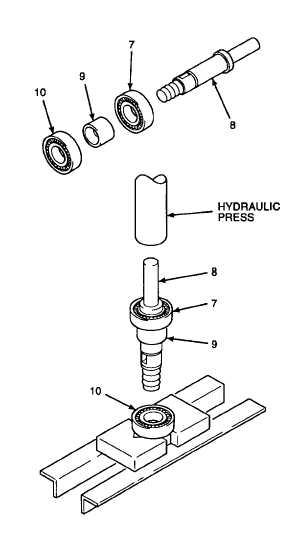

1.

INSTALL BEARINGS ONTO SHAFT.

a.

Place inner bearing (7) onto hydraulic press

frame.

b.

Press inner bearing (7) onto threaded end of

shaft (8) until it seats against shaft flange.

c.

Install spacer (9) against inner bearing (7).

d.

Press outer bearing (10) onto shaft until it

seats against spacer (9).

e.

Fill space between bearings half full with

grease.

GO TO NEXT PAGE

2-322