TM 5-3895-373-34

2.21.

REPAIR TURBOSUPERCHARGER - Continued

D.

ASSEMBLE.

2.

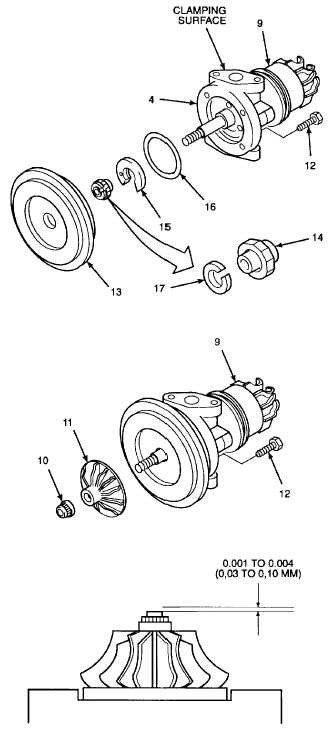

CLAMP COMPRESSOR HOUSING IN A BENCH

VISE AND INSTALL COMPRESSOR WHEEL AND

PLATE.

a.

Clamp flat surfaces of compressor housing (4)

in a vise.

b.

Lubricate

preformed

packing

(16)

with

petrolatum.

c.

Install preformed packing (16).

d.

Install ring (17) and bearing (15) onto collar

(14).

e.

Install assembled collar (14) onto compressor

housing (4).

f.

Slide plate (13) onto impeller shaft (9). Seat

firmly.

Thread locking compound can cause

eye

damage.

Wear

safety

goggles/glasses when using. Avoid

contact with eyes. If compound

contacts eyes, flush eyes with water

and get immediate medical attention.

g.

Apply thread locking compound to bolts (12).

h.

Install and securely tighten bolts (12).

i.

Install compressor wheel (11).

j.

Use engine oil to lubricate threads of impeller

shaft (9).

k.

Use a wrench to hold onto impeller shaft (9)

while installing lock nut (10) on opposite end of

impeller shaft. Tighten lock nut to 20 lb-in (2

N•m). Continue tightening through to a 110°

angle.

I.

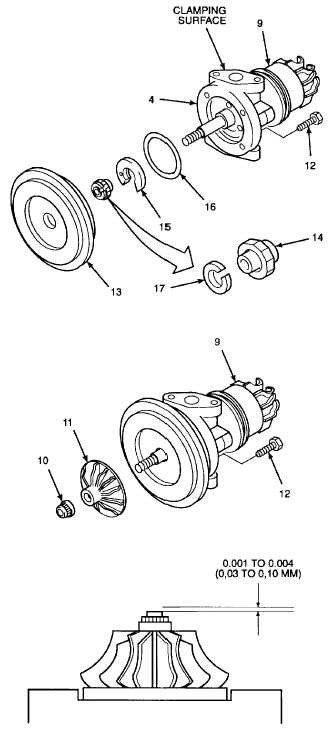

Use a depth gage and check for impeller shaft

endplay. Endplay should be 0.001 to 0.004 in

(0,03 to , 0,10 mm). If endplay is not within

specified

dimensions,

disassemble

turbosupercharger and replace impeller shaft

(9) with a new impeller shaft.

m.

Remove impeller housing from vise.

GO TO NEXT PAGE

2-304