TM 5-3895-373-34

D.

INSTALL.

1.

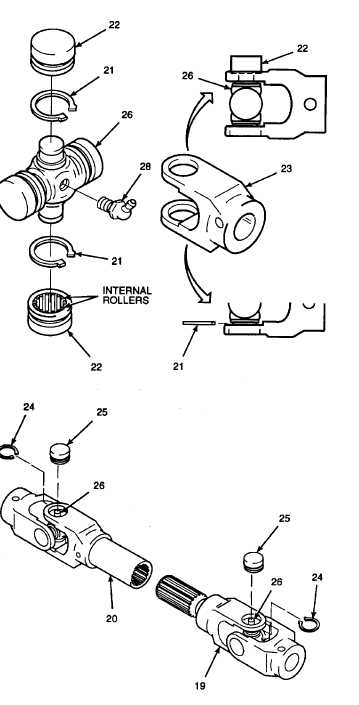

ASSEMBLE UNIVERSAL JOINT YOKES AND

SPIDERS.

NOTE

Use a bench vise as needed to assist

in assembling component parts.

a.

Install and tighten lubrication fittings (28) into

spiders (26).

NOTE

Use

care

when

removing

and

installing spider bearings. Internal

rollers could fall free. Keeping spider

bearings upright during installation

will prevent rollers from falling out.

b

Carefully remove spider bearings (22) from

spiders (26). Use care to avoid loss of internal

rollers.

c.

Position spiders (26) in outer yokes (23).

d.

Install spider bearings (22) through outer yokes

(23) and onto spiders (26). Make sure spider

bearings are installed far enough onto spiders so

that internal rollers do not fall.

e.

Place outer yokes into bench vise putting

pressure on spider bearings. Tighten bench vise

until spider bearing are flush with outer yokes.

Use care when installing snap and

retaining rings. Snap and retaining

rings are under spring tension and

can act as projectiles when released

and could cause severe eye injury.

f.

Install retaining rings (21).

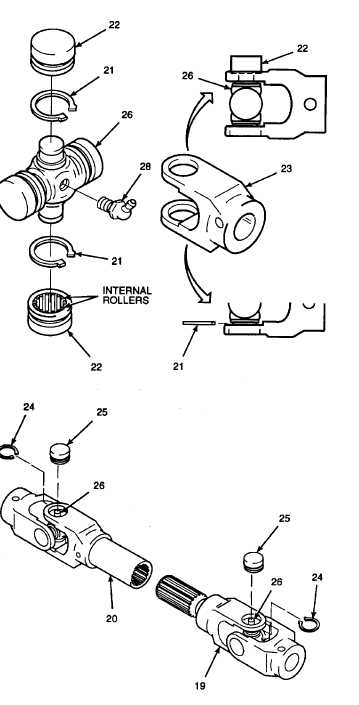

g.

Carefully remove spider bearings (25) from

spiders (26). Position internal spline yoke (20)

and external spline yoke (19) onto spiders.

h.

Install spider bearings (25). Make sure spider

bearings are installed far enough onto spiders so

that internal rollers do not fall.

i.

Place internal spline yoke (20) into bench vise

putting pressure on spider bearing. Tighten

bench vise until spider bearings are flush with

internal spline yoke. Repeat for external spline

yoke (19).

j.

Install retaining rings (24).

GO TO NEXT PAGE

2-1063