TM 5-3895-373-34

2.73 REPLACE EXTENSION SCREED GUIDE SHAFT SUPPORT, GUIDE SHAFTS, AND SLEEVE BUSHINGS -

Continued.

D.

INSTALL - Continued.

2.

INSTALL GUIDE SHAFT SUPPORT ASSEMBLY

AND

GUIDE

SHAFTS

INTO

THE

PAVING

MACHINE.

Thread locking compound can cause

eye

damage.

Wear

safety

goggles/glasses when using. Avoid

contact with eyes. If compound

contacts eyes, flush eyes with water

and get immediate medical attention.

a.

Apply thread locking compound to threads of

socket head cap screws (27).

b.

Install guide bars (28) and secure with socket

head cap screws (27).

c.

Tighten socket head cap screws (27) to 37 lb-ft

(50 N.m) using a socket wrench adapter (Item 7,

Appendix D) and hex head driver socket.

d.

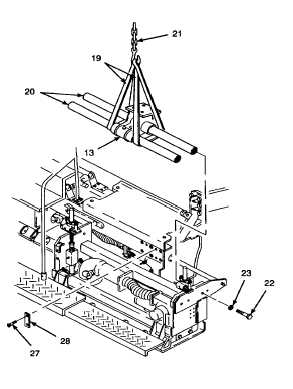

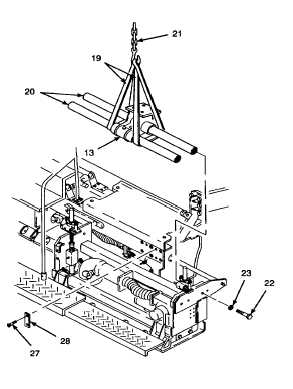

Place two sling straps (19) around portion of

guide shafts (20) up against guide shaft support

assembly (13).

e.

Place loop ends of sling straps (19) into hook of

overhead hoist (21).

Guide shafts weigh approximately

200 lbs (91 kg). Ensure sling straps

and guide shaft support are centered

on guide shafts while lifting. Guide

shafts may slide in guide shaft

support.

NOTE

When lifting the guide shaft support

assembly (13) and guide shafts (20)

into the paving machine, have a

second

person

reposition

any

hydraulic hoses and electrical wiring

that may interfere with installation.

It may be necessary to spread apart

extension

screed

frame

with

universal puller kit to allow for

installation of the guide shaft support

assembly.

f.

With the help of a second person as a guide, lift

the guide shaft support assembly (13) and guide

shafts (20) into the paving machine. Align the

guide shaft support assembly with guide bars

(28).

g.

Install lockwashers (23) onto hex head cap

screws (22).

h.

Apply thread locking compound to threads of hex

head cap screws (22).

i.

Install hex head cap screws (22) through the

outer walls of extension screed and into the ends

of guide shafts (20). Do not tighten at this time.

GO TO NEXT PAGE

2-1054