TM 5-3895-373-34

2.69

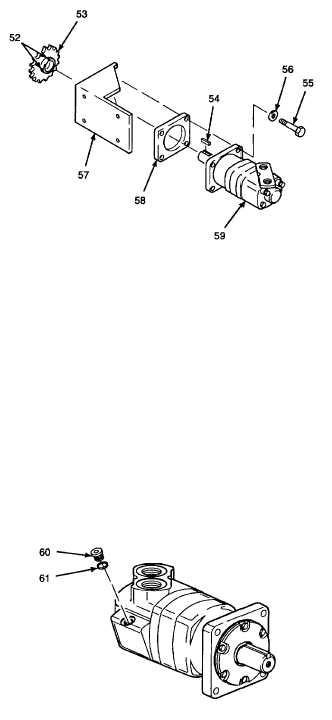

REPLACE/REPAIR AUGER/CONVEYOR MOTOR AND DRIVE SPROCKET WHEEL - Continued

B.

DISASSEMBLE.

1.

REMOVE

DRIVE

SPROCKET

WHEEL

AND

MOTOR

MOUNT

FROM

AUGER/CONVEYOR

MOTOR.

a.

Loosen set screws (52) and remove drive

sprocket wheel (53) and key (54).

b.

Remove hex head cap screws (55) and washers

(56).

c.

Remove motor mount (57) and shim (58) from

auger/ conveyor motor (59).

d.

Place

key

(54)

back

in

key

slot

on

auger/conveyor motor (59) drive shaft and

secure in place with masking tape.

Cleanliness is extremely important when

repairing a hydraulic motor. Work in a

clean area. Ensure all parts are coated with

clean hydraulic oil during disassembly to

avoid corrosion or contamination. Failure

to

do

so

may

result

in

excessive

component wear or failure.

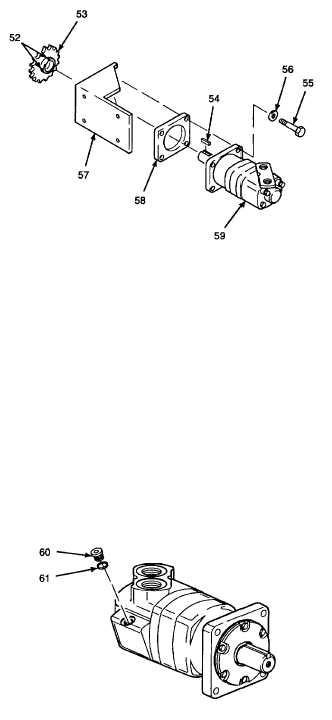

2.

DRAIN

HYDRAULIC

OIL

FROM

AUGER/

CONVEYOR MOTOR.

Hydraulic oil can be moderately flammable

and can be an irritant to the skin, eyes, and

respiratory

system.

Avoid

prolonged

exposure. Eye protection and rubber

gloves must be worn when working with

hydraulic oil.

a.

Remove fill/drain plug (60) and preformed

packing (61). Discard preformed packing.

b.

Drain hydraulic oil from auger/conveyor motor

into a drip pan. Dispose of hydraulic oil in

accordance with local procedures.

GO TO NEXT PAGE

2-978