TM 5-3895-373-20

A.

REMOVE Continued.

2.

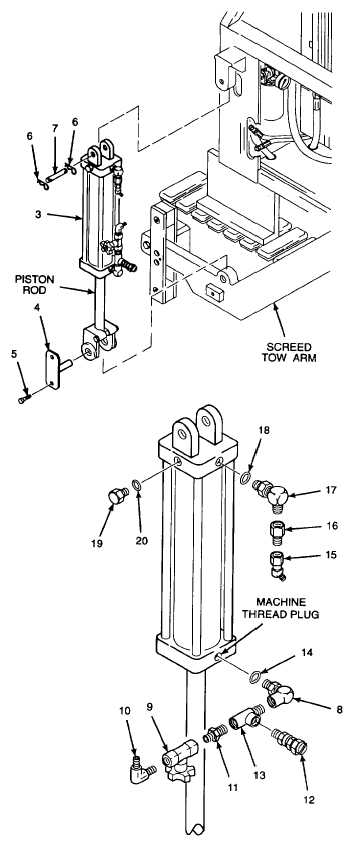

REMOVE TOW POINT CYLINDER.

a.

Ensure weight of screed is not on clevis pin (4)

at screed tow arm per step A.1.c.

b.

Remove hex head cap screw (5) and clevis pin

(4).

c.

Remove retaining clips (6) and clevis pin (7).

d.

Remove tow point cylinder (3).

Hydraulic

oil

can

be

moderately

flammable and can be an irritant to the

skin, eyes, and respiratory system.

Avoid

prolonged

exposure.

Eye

protection and rubber gloves must be

worn when working with hydraulic oil.

e.

Drain hydraulic oil from tow point cylinder into a

utility pail. Dispose of oil in accordance with local

procedures.

3.

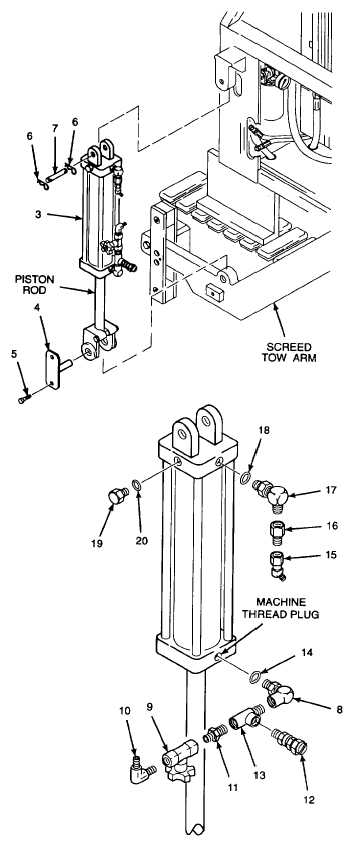

REMOVE GLOBE VALVE, RELIEF VALVE,

AND FITTINGS.

a.

Loosen lock nut and rotate elbow (8) about 90°

counterclockwise to allow room to unscrew

shutoff valve.

b. Remove globe valve (9) and elbow (10).

c. Remove pipe reducer (11), relief valve (12), and

tee (13).

d. Remove elbow (8) with lock nut and preformed

packing (14). Discard preformed packing.

e. Remove elbow (15) from tube reducer (16).

f.

Remove tube reducer (16) from elbow (17).

g. Remove elbow (17) with lock nut and preformed

packing (18). Discard preformed packing.

h. Remove plug (19) with preformed packing (20).

Discard preformed packing.

GO TO NEXT PAGE

13-5