TM 5-3895-373-20

15.21. REPAIR STRIKEOFF EXTENSION ASSEMBLY.

This task covers:

a. Disassembleb. Clean

c. Assemble

INITIAL SETUP

Tools:

References:

General mechanic's automotive tool kit

TM 5-3895-373-10

(Item 54, Appendix E)

TM 5-3895-373-24P

Torque wrench (Item 68, Appendix E)

Wire scratch brush (Item 6, Appendix E)

Equipment Condition:

Strikeoff extension assembly removed per TM 5-3895-373-10.

Materials/Parts:

Cleaning cloth (Item 7, Appendix C)

Cleaning solvent (Item 24, Appendix C)

Self-locking nuts

NOTE

There is a left hand and a right hand

strikeoff extension assembly. Only

remove strikeoff extension assembly

being repaired. This procedure

refers

to

repairing

right

hand

strikeoff extension. Procedure is

identical

for

left

hand

strikeoff

extension assembly. Right hand

strikeoff

extension

assembly

is

shown in this procedure.

A.

DISASSEMBLE.

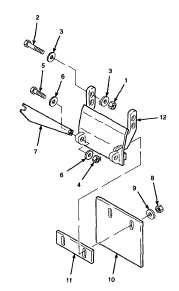

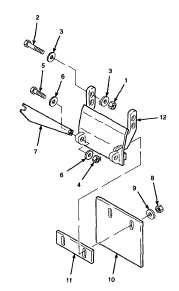

1.

REMOVE STRIKEOFF SUPPORT.

a.

Remove self-locking nuts (1), hex head cap

screws (2), and flat washers (3). Discard

self-locking nuts.

b.

Remove self-locking nut (4), hex head cap

screw (5), and flat washers (6). Discard

self-locking nut.

c.

Remove strikeoff support (7).

2.

REMOVE STRIKEOFF PLATE.

NOTE

Note offset of slots in strikeoff plate

before removing the self-locking

nuts. The slots are not equal

distance from each edge of the

strikeoff plate.

a.

Remove self-locking nuts (8) and flat

washers (9). Discard self-locking nuts.

b.

Remove strikeoff plate (10) and spacer bar

(11) from screed extension strikeoff (12).

GO TO NEXT PAGE

15-150