TM 5-3895-373-20

15.19. REPAIR SCREED EXTENSION PLATE.

This task covers:

a. Disassemble

b.

Clean

c. Inspect

d. Assemble

INITIAL SETUP

Tools:

References:

General mechanic's automotive tool kit

TM 5-3895-373-10

(Item 54, Appendix E)

TM 5-3895-373-24P

Torque wrench (Item 68, Appendix E)

Wire scratch brush (Item 6, Appendix E)

Equipment Condition:

Screed extension plate removed per TM 5-3895-373-10.

Materials/Parts:

Cleaning cloth (Item 7, Appendix C)

Cleaning solvent (Item 24, Appendix C)

Self-locking nuts

NOTE

This procedure applies to both the

left and right hand screed extension

plates. Only the right side is shown

in this procedure.

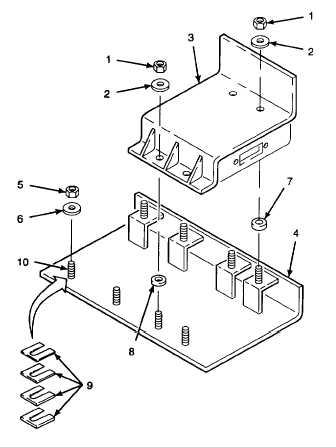

A.

DISASSEMBLE.

1.

REMOVE

SCREED

EXTENSION

BASE

FRAME.

a.

Remove self-locking nuts (1) and flat washers

(2). Discard self-locking nuts.

b.

Remove screed extension base frame (3) from

screed extension plate (4).

2.

REMOVE PLATE SPACERS.

NOTE

Plate spacers are used to align

screed extension plate with screed

plate on extension screed. There may

be no plate spacers or several plate

spacers on the screed extension

plate studs. If plate spacers are

removed, they must be returned to

the same locations from which they

were removed to maintain screed

plate alignment, or replaced with

plate spacers of like thickness.

a.

Remove self-locking nuts (5) and flat washers

(6). Discard self-locking nuts.

b.

Remove spacers (7 and 8). spacers.

c.

Remove

plate

spacers

(9)

from

screed

extension plate studs (10). Make a note of

locations of all

plate spacers.

GO TO NEXT PAGE

15-133