TM 5-3895-373-20

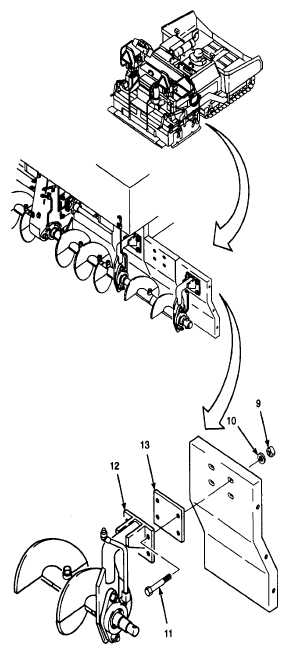

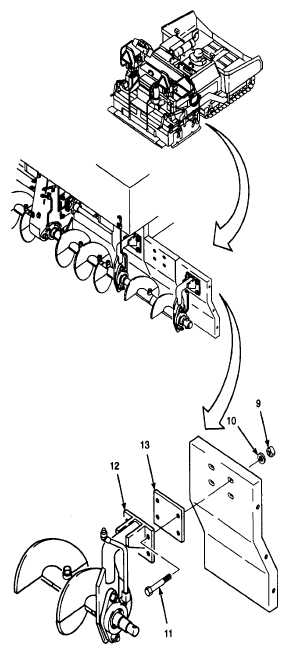

15.18. REPAIR TWO FOOT AUGER AND FENDER EXTENSION - Continued.

D.

ASSEMBLE Continued.

4.

ADJUST

2

FT

AUGER

AND

FENDER

EXTENSION.

a.

Install 2 ft auger and fender extension onto

paving machine per TM 5-3895-373-10.

b.

Operate auger system per TM 5-3895-373-10.

Observe rotation of 2 ft auger and fender

extensions and check for horizontal or vertical

wobbling during operation.

c.

Stop augers. Shut off engine and remove key

from ignition switch. Refer to TM 5-3895-373-

10.

d.

If horizontal wobbling is detected, remove hex

nuts (9) and slide bearing mount (12) until

wobbling condition is corrected. Install hex nuts.

Repeat steps b and c as required.

Thread locking compound can cause

eye

damage.

Wear

safety

goggles/glasses when using. Avoid

contact with eyes. If compound

contacts eyes, flush eyes with water

and get immediate medical attention.

e.

Apply thread locking compound to the threads of

hex head cap screws (11).

f.

Install and tighten hex nuts (9) to 90 lb-ft (122

N-m).

g.

If vertical wobbling is detected, remove hex nuts

(9), flat washers (10), and hex head cap screws

(11). Add or remove shims (13) until wobbling

condition is corrected. Install hex head cap

screws, flat washers, and hex nuts. Repeat

steps b and c as required.

h.

Apply thread locking compound to threads of

hex head cap screws (11).

i.

Install hex head cap screws (11), flat washers

(10), and hex nuts (9).

j.

Tighten hex nuts (9) to 90 lb-ft (122 N•m).

k.

If required, remove auger and fender extension

per TM 5-3895-373-10.

NOTE

FOLLOW-ON-TASK: Two foot auger and fender extension installed per TM 5-3895-373-10.

END OF TASK

15-132