TM 5-3895-373-20

C.

INSTALL - Continued.

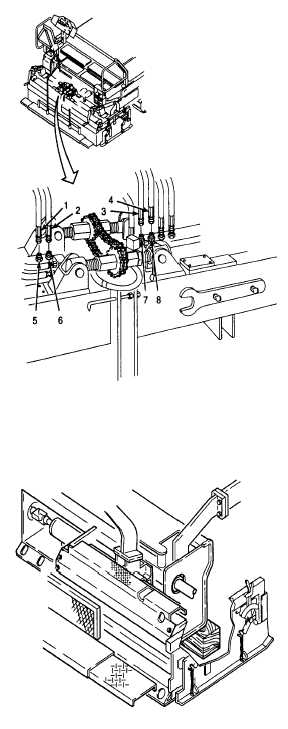

p.

Remove plugs from hoses (1 through 4) and

caps from mating straight adapters (5 through

8).

q.

Wipe threads of hoses and straight adapters dry

with cleaning cloths.

Hydraulic fitting sealant can cause

eye damage or skin irritation. Wash

after skin contact. Wear safety

goggles/glasses when using. Avoid

contact with eyes or skin. If sealant

contacts eyes, flush eyes with water

and get immediate medical attention.

r.

Apply hydraulic fitting sealant to straight adapters

(5 through 8). Install and tighten hoses (1

through 4).

D.

ADJUST.

1.

POSITION/BLOCK UP SCREED FOR CROWN

SETUP ADJUSTMENT.

NOTE

Refer to TM 5-3895-373-10 for detailed

paving

machine

operating

instructions.

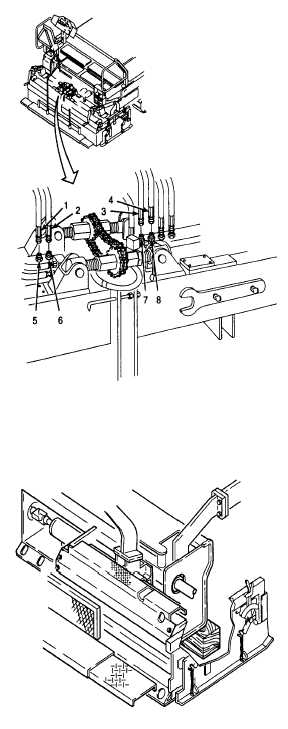

a.

Perform steps b through d by following the

paving machine operating instructions in TM 5-

3895-373-10.

b.

Start up paving machine. Raise screed to the

fully raised position. Fully extend screed

extensions.

Crown adjustment measurements are

performed from below main screed.

For safety purposes, the main screed

must

be

cribbed

during

this

adjustment procedure. Failure to

properly crib the main screed may

result in serious injury or death.

c.

Use cribbing of a size that will allow a mechanic

to work underneath the screed. Place cribbing

under the outside ends of the main screed. Do

not lower the screed onto the cribbing. The

screed has to be suspended without screed

plates making contact with cribbing in order to

perform zero crown adjustment.

GO TO NEXT PAGE

15-39