TM 5-3895-373-20

15.4.

REPLACE/REPAIR CROWN ADJUSTMENT ASSEMBLY - Continued.

C.

INSTALL.

1.

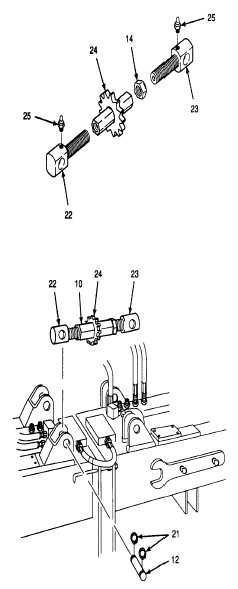

ASSEMBLE SPROCKET WHEEL AND BOLTS.

NOTE

The following procedure applies to

both the front and rear sprocket

wheel

assemblies.

The

only

difference is the hex nut is installed

on the rear sprocket wheel assembly.

a.

Apply thin coat of grease to left hand and right

hand fluid passage bolts (22 and 23).

b.

On rear sprocket assembly only, install hex nut

(14) on right hand fluid passage bolt (23).

c.

Screw right and left hand fluid passage bolts (22

and 23) into mating sides of sprocket wheel (24).

d.

Screw left hand and right hand fluid passage

bolts (22 and 23) to the same depth on both

ends of sprocket wheel (24). Count exposed

screw threads or use a steel ruler to ensure

matching bolt adjustments.

e.

Install lubrication fittings (25) into left and right

hand fluid passage bolts (22 and 23).

2.

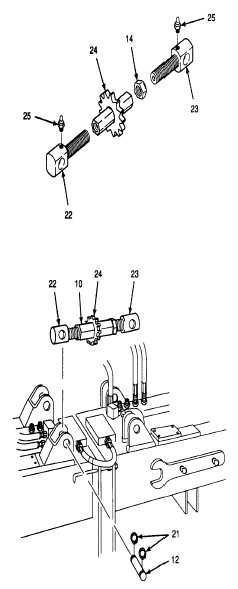

INSTALL SPROCKET WHEEL ASSEMBLY.

Right hand fluid passage bolts of

front

and

rear

sprocket

wheel

assemblies must be on the right side

of the screed. Failure to install right

hand fluid passage bolts on the right

side will make crown adjustments

impossible

and

may

result

in

equipment damage.

a.

Position rear sprocket wheel assembly (10) on

screed. Line up pin bore of left hand fluid

passage bolt (22) with its mounting bracket.

Use care when installing retaining

rings. Retaining rings are under

spring

tension

and

can

act

as

projectiles when released and could

cause severe eye injury.

b.

Install left side assembly mounting pin (12).

Install retaining rings (21) using snap ring pliers.

c.

Hold right hand fluid passage bolt (23) so that it

does not rotate. Adjust sprocket wheel (24) to

line up pin bore of the right hand fluid passage

bolt with its mounting bracket.

d.

Install right side assembly mounting pin (12).

Install retaining rings (21) using snap ring pliers.

GO TO NEXT PAGE

15-36