TM 5-3895-373-10

CAUTION

During installation of outer extension

screed plate, ensure that the spacers

and plate spacers around the studs

securing the outer extension screed

plate to the frame are to allowed to

move or fall from the stud. If spacers

or plate spacers are moved and not

returned to their initial position on

the screed plate, a screed alignment

is required.

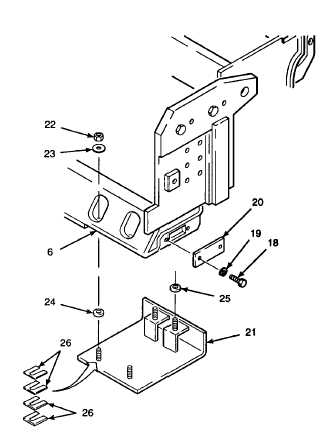

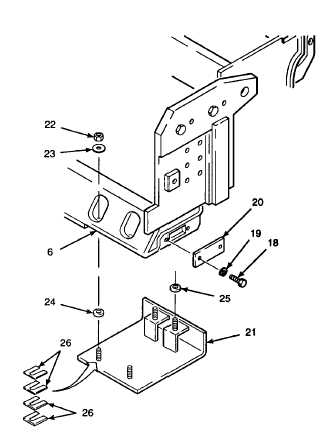

(5)

Remove self-locking nuts (22) and flat

washers (23) from outer extension screed

plate (21). Spacers (24 and 25) and plate

spacers (26) should be in place on outer

extension screed plate.

(6)

Raise outer extension screed plate (21) up

to extension screed frame (6) and secure

with flat washers (23) and self-locking nuts

(22).

(7)

Install cover plate (20) using lockwashers

(19) and hex head cap screws (18).

n.

Install endgate assembly using the following

steps.

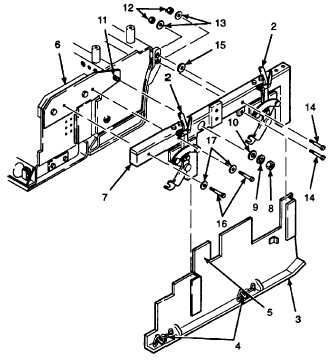

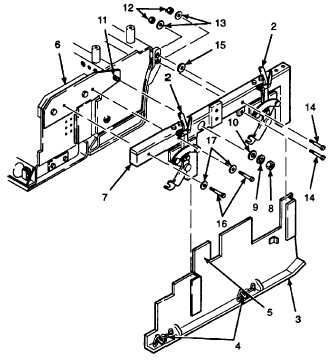

(1)

Remove hex nut (8), lockwasher (9), and

flat washer (10) from cylinder extension

rod (11).

WARNING

To avoid personal injury, do not

attempt to lift and install the endgate

support arm and endgate alone.

Endgate support arm and endgate

weighs approximately 126 lbs (57,1

kg). Use a second person to help

hold the endgate support arm and

endgate in place during installation.

Failure to do so may result in serious

injury.

(2)

With the help of a second person, lift

endgate (3) and endgate support arm (7)

onto extension screed frame (6), inserting

endgate mounting tab (5) into extension

screed

frame,

and

secure

with

flat

washers (17) and hex head cap screws

(16).

(3)

Install hex head cap screws (14), spacer

(15), flat washers (13), and self-locking

nuts (12).

(4)

Carefully level endgate (3) and connect

chains (4) to endgate hand levers (2).

(5)

Install flat washer (10), lockwasher (9),

and hex nut (8) onto cylinder extension rod

(11) and tighten hex nut.

2-93