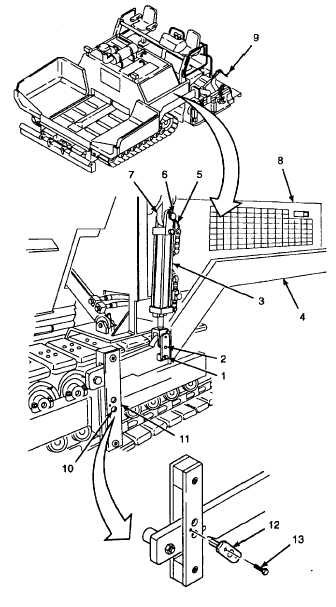

TM 5-3895-373-10

2.26.9 Pinninq the Tow Point. The tow point of the

paving

machine

can

be

converted

from

being

hydraulically controlled to being mechanically controlled

by pinning the tow point to the tractor. Mat thickness up

to 6 in. (152 mm) is achieved by hydraulically adjusting

the tow point cylinder. Pinning the tow point allows

mechanical mat thickness of 6 to 8 in. (152 to 203 mm)

by using the thickness control.

a.

Shut down paving machine and remove key from

ignition switch per paragraph 2.11.

b.

Access toolbox per paragraph 3.3.1 and retrieve

two screed tow arm locking pins with attached

hex head cap screw and wrench set from

toolbox.

NOTE

Procedures for pinning the tow point

are the same for both left and right

screed tow arms. Pin one side of the

machine at a time. The left side of

the machine is illustrated in this

procedure.

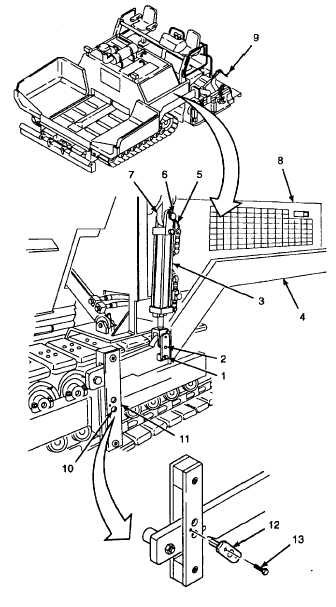

c.

Use a wrench to remove hex head cap screw (1)

and tow arm clevis pin (2) from bottom cylinder

clevis head.

d.

Pull forward on tow point cylinder (3) to slide

cylinder clevis head from screed tow arm (4).

e.

Pull top retaining clips (5) from top cylinder clevis

pin (6).

f.

Remove clevis pin (6).

g.

Pull down on tow point cylinder to disengage it

from mounting bracket (7).

h.

Pull tow point cylinder (3) backward and secure

cylinder to the side access cover (8) by clipping

retaining clips (5) through top and bottom clevis

heads and attaching to grill of side access cover.

i.

Use screed thickness control (9) to align bottom

locking pin hole (10) in tow arm support plate

(11) with slotted hole in screed tow arm (4).

j.

Install locking pin (12) into bottom hole in tow

arm support plate (11) and slotted hole in screed

tow arm (4).

k.

Use a wrench to install hex head cap screw (13)

into tow arm support plate and screed tow arm

and tighten.

I.

Repeat pinning procedure for opposite tow point

cylinder (3).

m.

Put wrench set back into toolbox and secure

toolbox per paragraph 3.3.1.

2-95