TM 5-3895-356-14&P

THE INSTALLATION - IF YOU DO, DAMAGE TO THE

SYSTEM WILL OCCUR.

B. COUPLING FIT

Your couplings, both pump and motor, must be a snug,

slip fit on the drive shaft Mounting flanges must be

concentric They also must be at right angles to both

the drive shaft and the output shaft Check for

concentricity and angle tolerance.

When you use

semiflexible couplings, maintain tolerances normally

required by the type connection you employ If you make

a direct coupling from the power shaft to the pump shaft,

you must use a dial indicator In this case, tolerances

must be within 0.001 in total indicator run-out Do not

proceed with installation until complying with stated

coupling fit tolerances.

C. MOUNTING

After the above conditions have been met, mount the

pump First grease the coupling with noncorrosive

grease, then bolt the pump to Its mounting flange Follow

the same procedure for mounting the motor, first

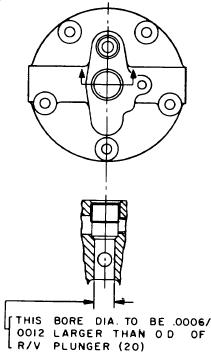

Figure 233.

greasing the coupling and then bolting the motor to its

High pressure relief valve tolerance

mounting flange.

This completes reassembly of the Dynapower motor.

D. USE GOOD HYDRAULIC PRACTICES

Be sure the interiors of reservoir, connections and fittings

PRECAUTIONS FOR RE-STARTING SYSTEM

are perfectly clean

Certain precautions should be taken prior to restarting

E. BEFORE OPERATION

your system after completion of a maintenance

Be sure all lines and connections are set up according to

operation.

your system layout

All of the procedures below should be followed If a

F. BE SURE SYSTEM IS FULL

complete overhaul of your system was performed Some

Completely fill the reservoir, being sure that all the fluid

of the more basic repairs do not require adherence to all

goes through the mesh or gauze strainer Loosen fitting,

of these procedures, however, you should review the

and bleed the line at the charge pump enough to check

material below and follow those steps which are

for presence of hydraulic fluid The fluid must have

pertinent.

arrived at this point to assure that the system can be

started without being damaged If no fluid Is present, It

A. ROTATION CHECK

may be necessary to apply air pressure to the tank Do

Make a careful comparison of the direction of rotation of

not apply more than 10 PSI If oil still Is not present,

your power source with reference to the direction of

check the entire line for possible plugging.

rotation shown by the arrow on the Dynapower charge

pump cover It is absolutely essential that direction of

G. DISCONNECT LOAD

rotation of power source be the same as that shown by

If possible, disconnect the motor coupling from whatever

the arrow on the charge pump cover.

shaft it Is attached to, so that the transmission may be

started without putting an excessively heavy load on it

CAUTION

Disconnecting the load at some other point beyond the

No matter whether your power source is diesel, gasoline,

motor or employing other means of minimizing load on

steam or electric, no matter If Its direction is clockwise or

the system also are acceptable Now - be sure the pump

counterclockwise - if the direction of your power source

control lever is In neutral position Recheck power source

rotation Is not the same as the direction shown on the

rotation to assure It matches with rotation indicated on

charge pump cover plate - DO NOT PROCEED WITH

the cover of the charge pump.

130