TM 5-3895-356-14&P

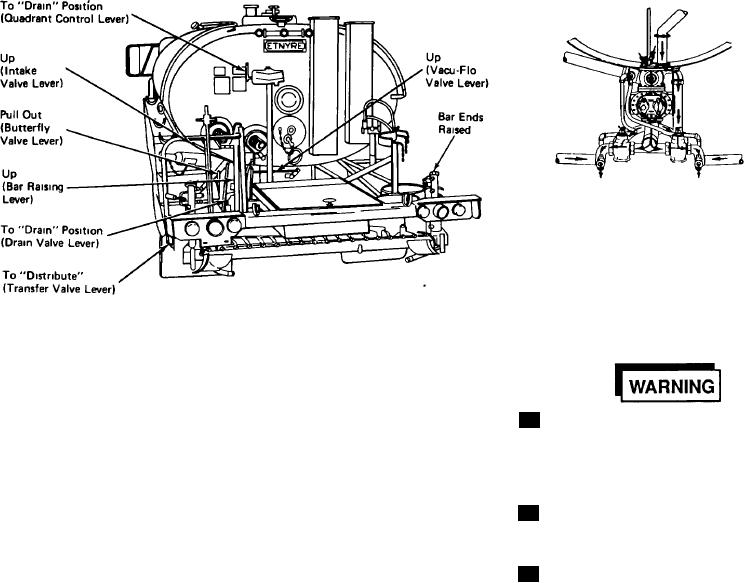

DRAINING CIRCULATIN SYSTEM AND SPRAY BAR

Figure 27

1. Raise Spray Bar and fold

up end sections, with "TUC" bar,

turn up bar before folding end

sections

Lit cigarettes or other sources of

3

2 Turn Vacu-Flo valve lever up.

combustion must remain clear of

open manholes or overflow vents

3 Pull out butterfly valve lever

to reduce fire hazard

4 Turn transfer valve lever to

Remain clear of rotating drives

5

"Dlstnbute" position

when unit is in operation to prevent

becoming entangled in machine.

5. If tank is also to be

drained, pull intake valve lever

Monthly check and If necessary

7

down If equipped with inside

clean 3" overflow tube to insure

closing valve, open by turning

tube has not become clogged.

counter-clockwise.

6. Turn quadrant

lever

to

"Drain" position

7. Pull the drain valve lever

rearward to "Dram" position

8. It is necessary to run the

pump for complete drainage of

circulating system Normal draining

speed is low idle

9. When draining operation is

completed, push forward dram

valve lever and turn quadrant

control lever to "Circulate In Bar"

position.

21