TM 5-3895-356-14& P

HYDROSTATIC MOTOR PRESSURE ADJUSTMENT

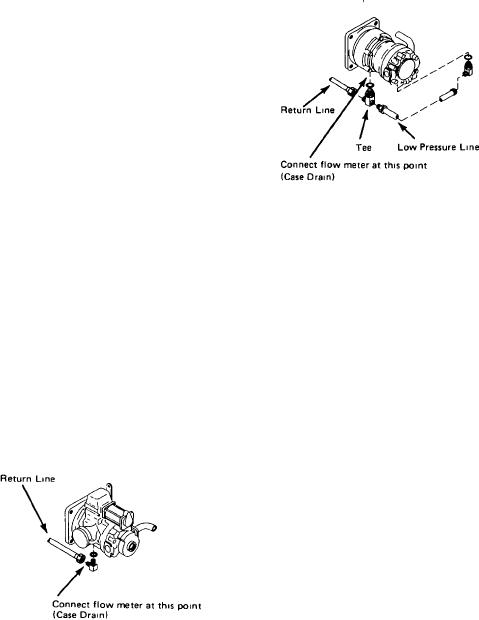

1. Disconnect case return line

of 1000 R P M. If not, set

Equipment required for pressure

indicated above.

truck engine at fast Idle.

check

2. Attach flow meter as noted or

4. Engage P T.O

1. 5000 P.S.I. pressure gauge.

direct dram flow into a

5. Pull out rear override control

2. 2 Ft. length of high pressure

container of known volume

until

hydraulic

motor

hose to fit gauge fitting and adaptor

for a given period of time,

pressure

registers

the

3. Anchor

adaptor

No

Then from dividing volume

highest reading This is by-

4BC4UFS or 6 BC4UFS or

by time, a flow rate can be

pass pressure.

equivalent.*

determined. If this flow rate

4. Anchor "O"-ring No. 383-4

PRESSURE EVALUATION

is above maximum allowed,

or M-383-6 or equivalent.*

With pressure gauge installed and

pump is worn internally and

5. Etnyre shim kit No. 740064.

hydraulic motor locked as indicated

should be replaced before

6. Vaseline or petroleum jelly.

above determine if by-pass pressure

proceeding

is actually low. If pressure Is not low

INITIAL PRESSURE CHECK

B. Motor case drain flow rate

consult "Trouble Shooting" section of

1. On bottom of hydraulic motor

this manual for other items which

check

remove right hand, 9/16" plug.

may cause hydraulic motor to turn

2. In this opening install a

slow or not at all If pressure is low

minimum

capacity 5000 P.S.I.

check the following two items before

gauge using appropriate Anchor

attempting

to

increase

relief

adaptor and "O"- ring with high

pressure.

pressure hose.

1. Air drawn into the hydraulic

3. Lock hydraulic motor by one

oil will cause it to appear

of the two following means and take

milky m color and result m

a pressure reading.

low system pressure To

A. MATERIAL IN DISTRIBUTOR

overcome this, check for air

TANK

leaks at four connections in

1. Set distributor controls on

the line from oil reservoir to

"Hand Spray" position See

Figure 31

filter to hydraulic pump.

section on "Hand Spraying"

Tighten fittings to eliminate

for additional information

1. Disconnect low pressure line

leaks

2. Transfer valve control (under

at motor tee If flow from this

2. Next check pump and motor case

left

operators

platform)

line Is directed into a clean

drain rate Maximum drain

remains in distribute position.

dry container the oil may be

rate is one-half (1/2) gallon

3. Accelerate to a minimum 100

saved and returned to the

per minute per 1000 P S I

G.P.M reading on pump

reservoir

Extreme

care

For example if the initial

Close

hand

should be taken to insure

pressure reading was 3000 P

spray

pressure

control

that while this line is

S I, the maximum allowable

"Butterfly Valve" slowly until

disconnected the hydraulic

flow rate would be 1 1/2 G.P

hydraulic

motor

stops

system is not accidentally

M

Highest reading on gauge is

pumped dry resulting m a

by-pass pressure setting on

damaged system

A. Pump case drain flow rate

hydraulic motor.

2. Disconnect return line and

check

remove tee from motor

B. EMPTY DISTRIBUTOR TANK

3. Connect flow meter as

1. On instrument stand in truck

indicated above or direct flow

cab pull pump control knob

from tee port (case dram)

to its uppermost position.

into a container of known

Adjust fine control tube up

volume for a given period of

until it is against bottom of

time Then from dividing

hydraulic control knob.

volume by time a flow rate

2. At the rear of distributor lock

can be determined. If this

universal coupling between

flow rate is above maximum

Etnyre pump and hydraulic

allowed motor is worn

*Select appropriate adaptor and

Figure 30

internally and should be

"O"-ring for the hydraulic motor

replaced before proceeding

motor with a pipe wrench of

sufficient length to lay

against left distributor frame.

3. If

truck

engine

has

tachometer, set to minimum

25