TM 5-3895-356-14&P

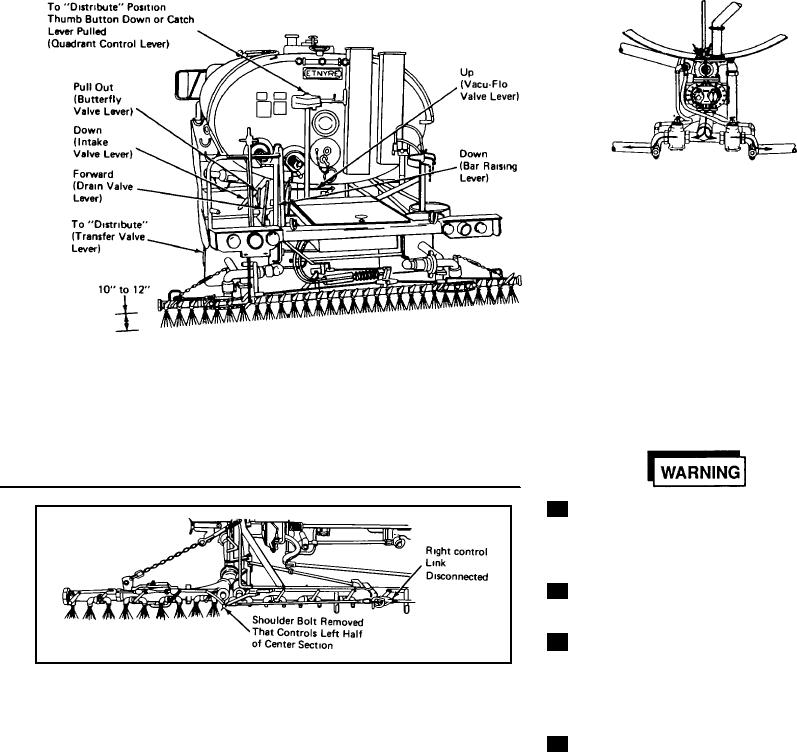

SHOULDER SPRAYING'

3. Remove pull pin on

connecting link between center half

and outer bar section on side that

is to spray 4.

Follow normal

spraying procedure

5. To spray center 6 foot

section only, remove pull pins from

connecting links between center

and outer bar sections

6. On units with "TUC" bars

Figure 22

equipped with flip valves on hinge

section and/or hook sections it is

1. Two

special

shoulder

necessary to disengage flip levers

spraying control links are provided

out to the control toggle on hook

The longer link is used to spray

dard Control Links from center

section before installing the

shoulders on the left, the shorter

fulcrum and place them in hanger

shoulder spray linkage

link for shoulders on the right To

on center control bars

use - disconnect Stan-

2. Place appropriate shoulder

link on center fulcrum

6

Remain clear of rotating drives

when unit is m operation to prevent

becoming entangled m machine

Monthly check and if necessary

7

clean 3" overflow tube to insure

tube has not become clogged

11

Keep area clear of open flame or

sparks when spraying material with

Figure 23.

volatile cutbacks to reduce fire

1. Disconnect control linkage

hazard.

for side not to spray by removing

bar. This disconnects half of center

corresponding pin in center

section that would otherwise spray

Spray bar on-off operation with air

fulcrum.

3. Follow

normal

spraying

15

will cause control lever on quadrant

procedures

2. On side to spray, remove

4. To spray center 6 foot section

to move rapidly Remain clear at all

shoulder bolt connecting control

only, remove both shoulder bolts

times to prevent injury.

linkage that connects to center

controlling valves in end sections.

section bus

17