TM 5-3895-356-14&P

2. Blow and Pilot Hand Valve

4. Air pressure should be

and turn this nozzle until you secure

3, Auxiliary Shut-Off Hand Valve

sufficient to slightly raise air relief

the type of flame you desire.

valve. Excess engine speed will

11. Do

not

leave

burners

raise relief valve too much, causing

unattended.

excessive

pressure.

Do not

12. Do not heat bitumen over

increase weights on air relief valve or

maximum

spraying

temperature

wire weights down.

23 recommended by supplier

5. Fuel pressure should not be

13. Do not remove material from

21 tank while burners are in operation or

excessive High fuel pressure will

make needle valve adjustment more

automatic burner controls are set to

LIQUID PETROLEUM BOTTLE RACKS

sensitive Recommended pressure is

operate

AND CONTROLS

10 to 15 P.S.I Pressure is determined

14. To shut off burners, turn fuel

1. Manual Throwover

by pressure relief valve located in

off before stopping blower or turning

Figure 17

Manifold Valve

return line. An adjusting screw and

off air .

2. Burner Pressure

lock nut are inside dome-shaped

15. When burners are not m

Regulator Control

cap.

use, close heat exhaust stack cover

3. Regulated Pressure Gauge

4 Bottle Rack

6. Do not light burners unless

to prevent loss of heat and to keep

you are sure flues are covered at

water from entering stack opening

20

6. The valve on the supply tank

least 6" the full length of tank On

Liquid Petroleum Burners

or bottle should be opened only a

tanks having "High-Low" flues it is

23

1

23

quarter of a turn so that it may be

10

necessary to cover only the lower

1. The burners are designed for

closed quickly m case of a leak.

flue with 6" of material when using

use with liquid only and must not be

7. After opening the supply

the lower (or inside) burner

25

used with vapor

valve ,and checking quickly for leaks,

7. Open

covers

on

heat

2. Circulating bitumen m tank

26 light ,the burners As soon as the

exhaust stacks

while heating is recommended for

burner is ht, open the hand valve at

8. To light burners, first turn air

faster heating and reduced carbon

the burner to the full position. No

* butterfly valves to No 1 or No. 2

formation on flues Only when the

preheating is necessary

25

open position, light torch and hold

asphalt pump is "frozen" is It

26

under burner tip, turn needle valve

acceptable to operate burners

about one-half turn. Burner should

without circulating material However,

ignite Immediately. If it does not, turn

in this case free the asphalt pump by

off needle valve and wait until vapor

applying heat to pump housing and

is exhausted from flues, then try

start circulating as soon as possible

again The correct opening of the

3. Do not light burners unless

needle valve is determined by fuel 20 you are sure flues are covered at

pressure. Experience is the only way

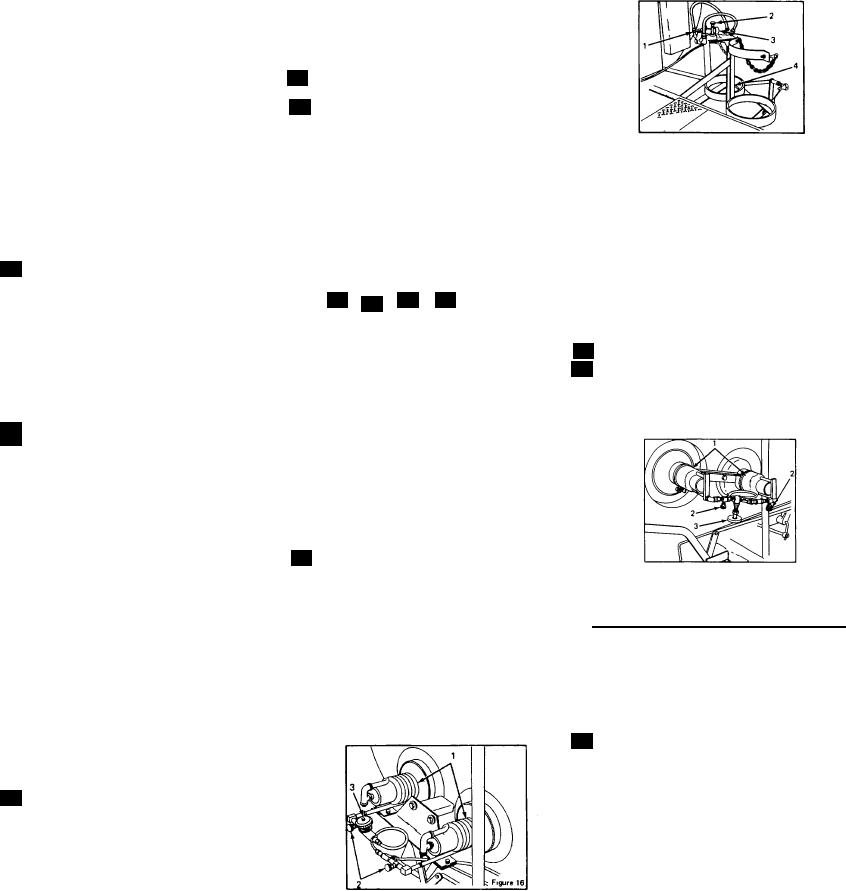

LIQUID PETROLEUM BURNERS (B) 1

least 6" the full length of tank On

Figure 18

of determining the amount for your

Burners

tanks having "High-Low" flues It is

2 Blow and Pilot Hand Valves

particular unit Flame at first will be

necessary to cover only the lower

3 Auxiliary Shut-off Hand Valve

yellow and smoky Adjust the fuel

flue with 6" of material when using

valve so that' flame is bright orange

the lower (or inside) burner

(Caution The burner must be ht

with slight smoke in exhaust More-

4. Open

covers

on

heat

before opening hand valve at the

fuel will be needed as flues and tank

exhaust stacks

burner This valve has a built in by-

contents heat up. Keep opening fuel

5. Before lighting burner, be

pass and permits only enough gas to

adjustments for slight smoke in

sure hand valve at burner is closed

escape to operate as a pilot or stand-

exhaust

tight

27 by. This by-pass hole must be kept

Important

open to prevent damage to the

If burner goes out, turn off fuel

gauge and supply lines After

valve immediately and do not attempt

shutdown and before relighting

to relight until vapor is exhausted

27

burner, valve at burner must be

from flues'

closed )

9. For larger flame, increase air

8. Open supply valve at tank or

butterfly valve opening and fuel valve

bottle fully and regulate pressure so

in equal increments, always keeping

that the gauge reads between 25 to

mix that will give slight smoke to

40

exhaust

LIQUID PETROLEUM BURNERS A)

10. Nozzle

of

burner

is

Figure 16

1. Burners

adjustable for amount of secondary

12

air desired Normally the secondary

air is in the full open position

However, on some smaller units it

may be desirable to reduce the

amount of secondary air Light burner