TM 5-3895-356-14&P

CIRCULATING IN TANK

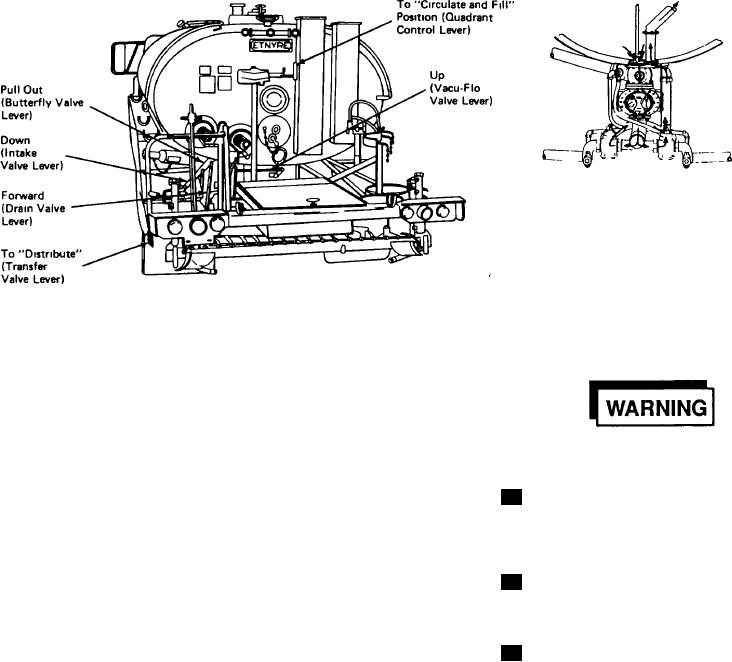

Figure 19.

For Heating

Engine Drive

Material will heat more rapidly

To set engine governor for

if circulated m tank when burners

spraying requirements.

are operating Circulate at 100 to

160 G P.M.

With material circulating in

tank regulate governor setting until

desired pumping rate appears on

Setting Engine Governor

Or

pump tachometer

Hydrostatic Controls

Lit cigarettes or other sources of

3

combustion must remain clear of

To set engine governor or

open manholes or overflow vents

hydrostatic controls for spraying

to reduce fire hazard

requirements when circulating m

tank, pump speed should be

Remain clear of rotating drives

5

when unit is m operation to prevent

10 to 15 G P M. per foot of bar

becoming entangled m machine.

length

with 1/8" nozzles

Fill line cap or connection must be

13

securely attached before operating

Example

intake valve lever to eliminate

160 to 240 G.P.M. for 16 foot

momentary discharge

spray bar length.

15 to 20 G P.M per foot of bar

length with 3/16" nozzles.

Example

240 to 320 G P.M. for 16 foot

spray bar length

7 to 10 G.P.M per foot of bar length

with 3/32" nozzles

Example

112 to 160 GP M. for 16 foot spray

bar length

14