TM 5-3895-385-23-1

0011

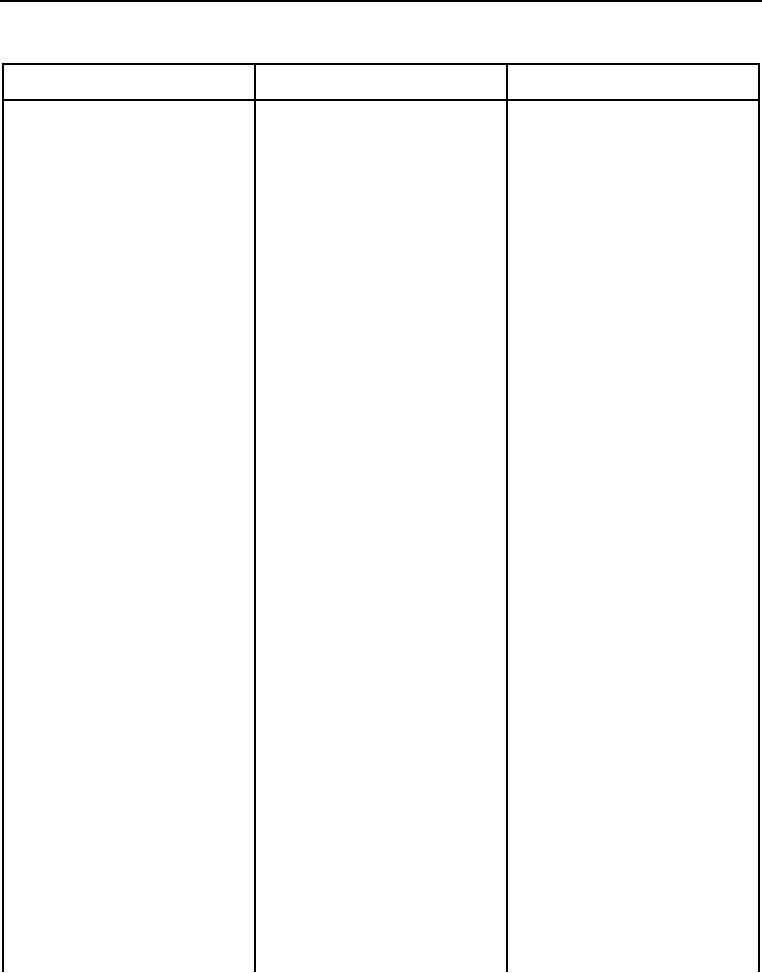

Table 1. SPN#100, FMI#1 ― Low Oil Pressure -- Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3. Inspect oil pressure switch and

1. If damaged, replace oil

connector pins for damage.

pressure switch (WP 0333, Vol

2).

2. If no damage is found, proceed

to next malfunction.

9. Switch supply voltage error.

1. Install fuse box (WP 0277, Vol

2).

2. Connect battery cables (WP

0357, Vol 2).

3. Turn keyless engine switch to

AUX position (TM 5-3895-385-

10), but do not start engine.

Wait for 30 seconds.

4. Measure voltage between oil

1. If voltage is between 4.75 Volts

pressure SIGNAL pin (pin 1) on

Direct Current (VDC) and 5.25

W25 C13 and engine block

VDC, turn keyless engine

ground (WP 0443, Vol 3 and

switch to OFF position (TM 5-

WP 0451, Vol 3, Figure 46).

3895-385-10), and replace oil

pressure switch (WP 0333, Vol

2).

2. If voltage is not between 4.75

VDC and 5.25 VDC, turn

keyless engine switch to OFF

position (TM 5-3895-385-10),

and go to next malfunction.

10.ECM and engine harness

1. Disconnect engine ECM wiring

connector pins damaged.

harness connector W25 C1

from ECM (WP 0451, Vol 3,

Figure 45).

2. Inspect engine ECM connector

1. If damaged, replace engine

pins for damage.

ECM (WP 0332, Vol 2).

2. If no damage is found, proceed

to the next test.

3. Inspect engine ECM wiring

1. If damaged, replace the engine

harness connector W25 C1 and

ECM wiring harness (WP 0334,

pins for damage.

Vol 2).

2. If no damage is found, proceed

to the next malfunction.

0011-3