TM 5-3895-385-23-1

0011

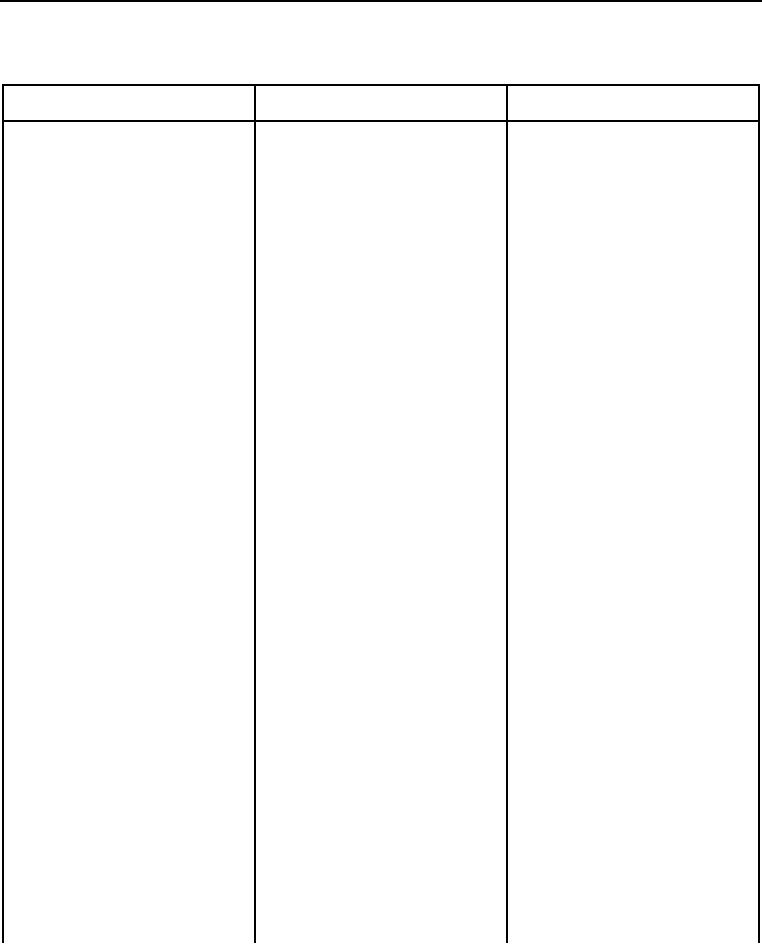

Table 1. SPN#100, FMI#1 ― Low Oil Pressure -- Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2. If not damaged or leaking,

proceed to next malfunction.

3. Oil pan leaking.

Inspect oil pan for cracks or leaks

1. If damaged or leaking, replace

(WP 0340, Vol 2).

oil pan (WP 0340, Vol 2).

2. If not damaged or leaking,

proceed to next malfunction.

4. Oil pan plug leaking.

Inspect oil pan plug for leaks or

1. If damaged, replace oil pan plug

damage (WP 0340, Vol 2).

(WP 0340, Vol 2).

2. If not damaged, proceed to next

malfunction.

5. Oil filter damaged.

Inspect oil filter for damage and

1. If damaged or leaking, replace

leaks (WP 0341, Vol 2).

oil filter (WP 0341, Vol 2).

2. If oil filter is not damaged or

leaking, proceed to next

malfunction.

6. Oil filter not installed properly.

Check oil filter for proper

1. If oil filter is properly installed,

installation (WP 0341, Vol 2).

proceed to next malfunction.

2. Install oil filter properly (WP

0341, Vol 2).

7. Crankshaft front oil seal leaking.

Inspect crankshaft front oil seal for

1. If leaking, replace crankshaft

oil leak (WP 0324, Vol 2).

front oil seal (WP 0324, Vol 2).

2. If no oil leak at front end of

crankshaft, proceed to next

malfunction.

8. Oil pressure switch or

1. Disconnect engine ECM wiring

connector pins dirty or

harness connector W25 C13

damaged.

from oil pressure switch (WP

0451, Vol 3, Figure 46).

2. Inspect engine ECM wiring

1. If damaged, replace engine

harness connector W25 C13 for

ECM wiring harness (WP 0334,

damage.

Vol 2).

2. If no damage is found, proceed

to next test.

0011-2