TM 5-3895-385-23-1

0012

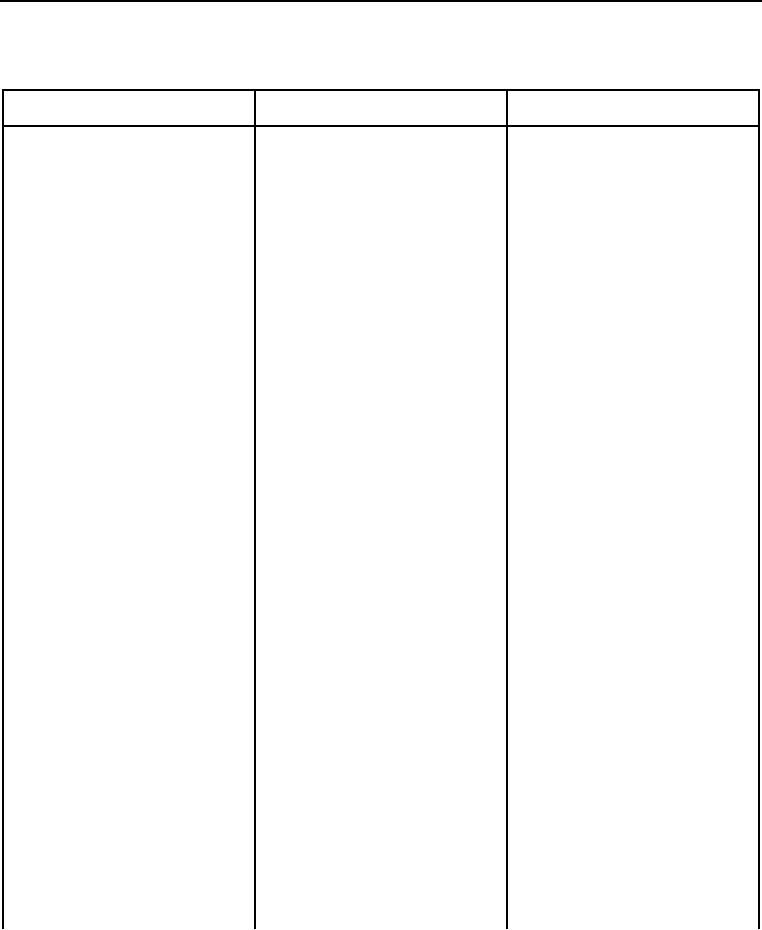

Table 1. SPN#100, FMI#2 ― Oil Pressure Switch Sensor Circuit Error -- Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3. Inspect engine ECM wiring

1. If damaged, replace ECM

harness connector W25 C13 for

wiring harness (WP 0334, Vol

damage.

2).

2. If no damage is found, proceed

to next malfunction.

2. Incorrect resistance error in oil

Measure resistance between

1. If resistance is 10 Ohms (Ω) or

pressure switch.

engine oil pressure SIGNAL pin

more, replace oil pressure

(pin 1) of engine oil pressure

switch (WP 0333, Vol 2).

switch and ground (WP 0443, Vol

3 and WP 0448, Vol 3, Figure 14).

2. If resistance is less than 10 Ω,

proceed to next malfunction.

3. Engine ECM fault.

1. Disconnect engine ECM wiring

harness connector W25 C1

from engine ECM (WP 0451,

Vol 3, Figure 45).

2. Inspect engine ECM wiring

1. If damaged, replace engine

harness connector W25 C1 and

ECM wiring harness (WP 0334,

connector pins for damage.

Vol 2).

2. If no damage is found, proceed

to next test.

3. Inspect engine ECM connector

1. If damaged, replace engine

and connector pins for damage.

ECM (WP 0332, Vol 2).

2. If no damage is found, proceed

to next malfunction.

4. Open circuit in engine ECM

Measure resistance between

1. If resistance is 10 Ω or more,

wiring harness.

engine oil pressure SIGNAL pin

replace engine harness (WP

(pin 1) at engine ECM wiring

0334, Vol 2).

harness W25 C13 and engine oil

pressure SIGNAL pin (pin 17) at

engine harness W25 C1 (WP

0443, Vol 3 and WP 0448, Vol 3,

Figure 15).

2. If resistance is less than 10 Ω,

proceed to next malfunction.

0012-2