TM 5-3895-373-34

C.

INSPECT - Continued.

2.

INSPECT EXTENSION SCREED BASE.

a.

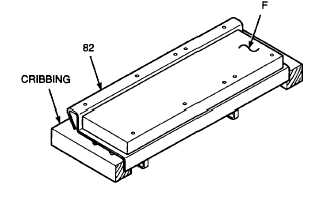

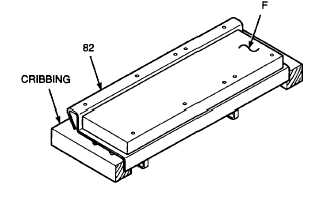

Turn extension screed base (82) upside down.

Support screed base with cribbing.

b.

Place straightedge diagonally between corners,

along bottom surface F. If any point on

surface F is not within 1/16 in. (1, 6 mm) of

the straightedge, replace warped extension

screed base.

c.

Visually inspect extension screed base (82) for

cracks, breaks, or holes. If cracks, breaks,

holes, other indications of damage are found,

replace screed base.

3.

INSPECT EXTENSION SCREED PLATE.

a.

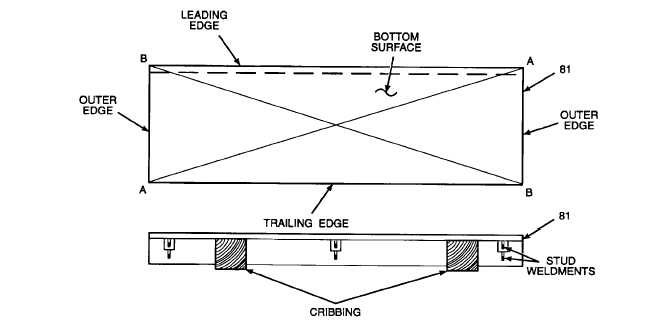

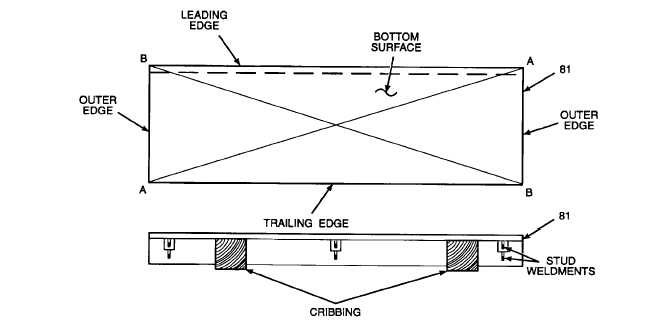

Place extension screed plate (81), bottom up,

on a flat surface.

b.

Place

a

straightedge

diagonally

across

extension screed plate (81) along lines A-A

and B-B. If any surface deformity along line A-

A or B-B is greater than 0.060 in. (1,5 mm),

replace warped screed plate.

c.

Inspect bottom surface of extension screed

plate (81) the for cracks or holes. If cracks or

holes are seen, replace screed plate.

d.

Turn extension screed plate (81) over. Inspect

stud weldments for weld cracks. If weld

cracks are seen, replace screed plate.

e.

Inspect leading, trailing, and outer edges of

extension screed plate (81) for dents that

would affect the smoothness of the paving

mat. If dents or other flaws are found, replace

screed plate.

GO TO NEXT PAGE

2-909