TM 5-3895-373-34

2.66.

REPLACE EXTENSION SCREED FRAME - Continued

A.

REMOVE - Continued.

11.

REMOVE

EXTENSION

SCREED

HYDRAULIC

LINES AND FITTINGS.

a.

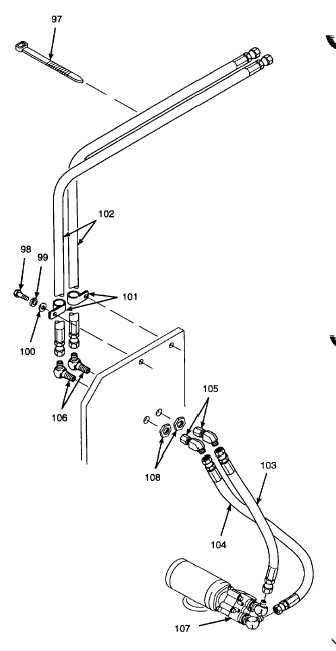

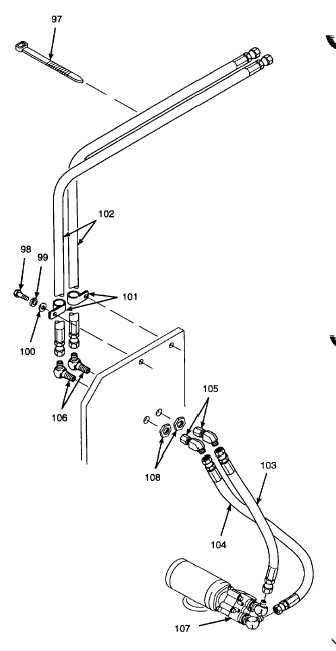

Cut tie wraps (97).

b.

Remove

hex

head

cap

screws

(98),

lockwashers (99), and flat washers (100)

securing clamps (101). Discard lockwashers.

Thoroughly clean hydraulic hoses and

fittings before disconnecting. Always

plug or cap off disconnected fittings to

prevent dirt and contaminants from

entering the system. Failure to clean

hoses and fittings, and plug or cap open

fittings may result in hydraulic system

contamination and equipment damage.

c.

Wipe fittings of hydraulic hoses (102, 103, and

104)

clean

with

cleaning

cloth.

Place

machinery wiping towel beneath hoses.

NOTE

Fittings of hoses (102, 103, and 104) at

swivel elbows (105) and elbows (106)

should be tagged "front" and "rear".

d.

Tag and remove hoses (103 and 104) from

swivel elbows (105). Tag and remove hoses

(102) from elbows (106).

e.

Tag and remove hydraulic hoses (103 and 104)

from extension screed vibration motor (107).

Remove hoses from extension screed.

f.

Remove swivel elbows (105) from elbows

(106).

g.

Remove lock nuts (108) from elbows (106).

Remove elbows from extension screed.

h.

Plug hoses and cap elbows to prevent

hydraulic system contamination. If saturated,

dispose

of

machinery

wiping

towel

in

accordance with local procedures.

GO TO NEXT PAGE

2-904