TM 5-3895-373-34

2.66.

REPLACE EXTENSION SCREED FRAME - Continued

C. INSPECT.

1.

INSPECT EXTENSION SCREED FRAME.

a.

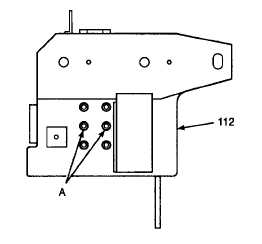

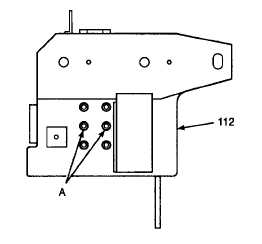

Install four 3/8-16 UNC x 4 in. hex head cap

screws in holes A, located at each end of

extension screed frame (112). Secure each

cap screw with a 3/8-16 UNC hex nut on each

side of extension screed frame plate.

b.

Suspend extension screed frame (112) on

inspection angle plates. The screed frame

must be supported only by the hex head cap

screws installed in holes A.

c.

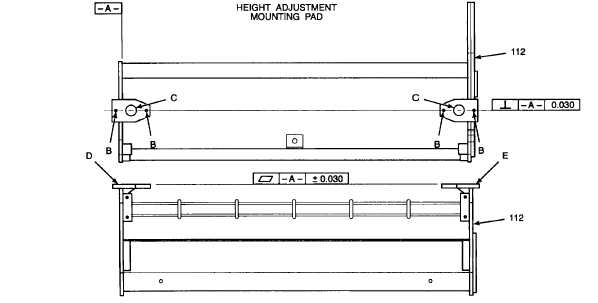

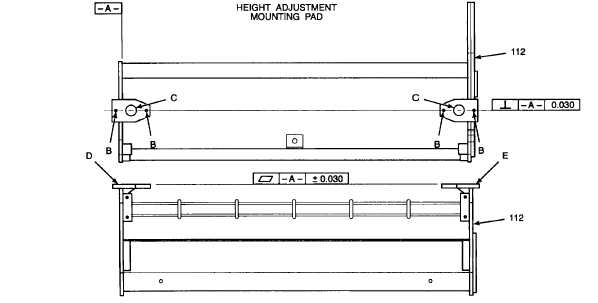

Check for perpendicularity between surface A

and the lines that pass through the centers of

threaded holes B and bores C of each height

adjustment mounting pad.

If

either

mounting

pad

centerline,

when

projected 46 in. (1168 mm) from surface A, is

not within 1/16 in. (1,6 mm) of the line

perpendicular to surface A, replace warped

screed frame.

d.

Place a straightedge (at least 4 feet long)

across surfaces D and E. If any point on

surface D or E is not within 1/16 in. (1,6 mm)

of the straightedge, replace warped extension

screed frame.

e.

Visually inspect extension screed frame weld

joints for cracks or breaks. If cracks or breaks

are

found,

replace

screed

frame.

GO TO NEXT PAGE

2-908