TM 5-3895-373-34

E.

ASSEMBLE - Continued.

5.

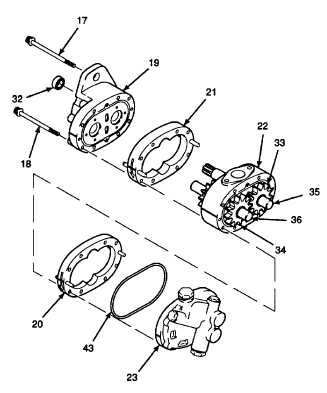

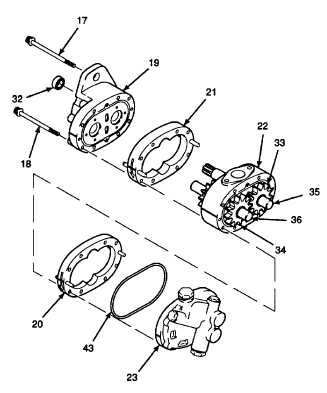

ASSEMBLE BACKPLATE ASSEMBLY, ADAPTER

PLATE ASSEMBLY, AND FRONT PLATE ASSEMBLY.

a.

Apply petrolatum to preformed packing (43).

Install packing in mating groove of backplate

assembly (23).

Hydraulic

oil

can

be

moderately

flammable and can be an irritant to

the

skin,

eyes,

and

respiratory

system. Avoid prolonged exposure.

Eye protection and rubber gloves

must be worn when working with

hydraulic oil.

b.

Dip adapter plate assembly (22) with installed

drive and idler gears (33 and 34) and drive and

idler gear assemblies (35 and 36) in clean

hydraulic oil.

NOTE

Pump

components

must

be

assembled in same positions as they

were prior to disassembly.

c.

Apply a thin coat of clean hydraulic oil to insides

of pump bodies (20 and 21).

d.

Align matchmarks on adapter plate assembly

(22) and installed rear pump body (20) with

backplate assembly (23). Install backplate

assembly on assembled adapter plate assembly

and pump body.

e.

Align matchmarks and join front plate assembly

(19) and installed front pump body (21) with

adapter plate assembly (22).

NOTE

Longer hex head cap screws (17) are

installed inside pilot diameter of

pump mounting flange f. Install hex

head cap screws (18 and 17). Tighten

to 26 lb-ft (35 N•m).

g.

Lubricate shaft seal (32) with clean hydraulic oil.

Use caution when installing shaft

seal. Sharp edges on drive shaft may

cut seal. Install shaft seal slowly. Do

not use excessive pressure to install

shaft seal.

h.

Using 3/4 in. deep well socket install shaft seal

(32) over shaft of drive gear assembly (35) and

into bore of front plate assembly (19). Tap on

3/4 in. deep well socket until shaft seal is fully

seated. Ensure spring loaded lip faces front

plate assembly.

i.

Rotate shaft of drive gear assembly (35) by

hand. Shaft should have slight resistance.

GO TO NEXT PAGE

2-579