TM 5-3895-373-34

2.33

REPLACE/REPAIR SPEED REDUCTION GEARBOX - Continued.

E.

ASSEMBLE Continued.

q.

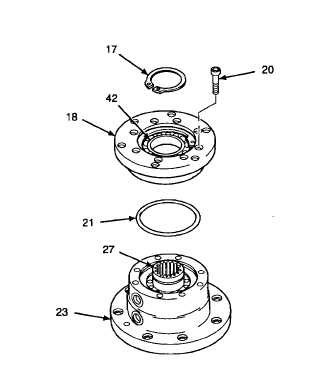

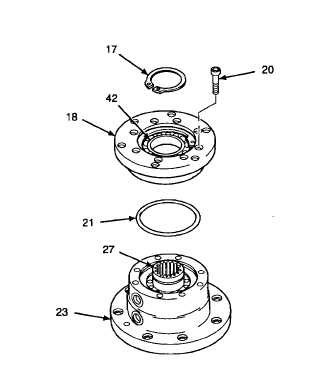

Lubricate o-ring (21) with petrolatum. Install o-

ring in mating groove of mechanical drive

housing (18).

Thread locking compound can cause

eye

damage.

Wear

safety

goggles/glasses when using. Avoid

contact with eyes. If compound contacts

eyes, flush eyes with water and get

immediate medical attention.

r.

Apply thread locking compound

(Item

14,

Appendix B) to threads of bolts (20).

s.

Center installed bearing (42) on shouldered shaft

(27). Lightly and evenly tap around perimeter of

mechanical drive housing (18) with plastic

hammer until housing is close enough to install

bolts (20).

t.

Make sure o-ring (21) is still seated in mating

groove of mechanical drive housing (18).

u.

Install and evenly tighten bolts

(20)

until

mechanical drive housing (18) is fully seated on

brake housing (23). Using hex head driver

socket (Item 89, Appendix D), evenly tighten

bolts to 8 Ib-ft (11 N•m).

Use care then installing retaining rings.

Retaining rings are under spring tension

and can act as projectiles when released

and could cause severe eye injury.

v. Using snap ring pliers, install retaining ring (17).

Hydraulic

oil

can

be

moderately

flammable and can be an irritant to the

skin, eyes, and respiratory system.

Avoid

prolonged

exposure.

Eye

protection and rubber gloves should be

worn when working with hydraulic oil.

w. Use HSTRU to pressure test brake at 350 psig

(2413 kPa gauge) for leakage. Apply pressure

at hydraulic adapter port. If hydraulic oil leakage

is detected at either end of brake housing after 5

minutes, failed preformed packings must be

replaced.

x. Disconnect brake from HSTRU and drain

hydraulic oil into drain pan. Dispose of drained

hydraulic oil in accordance with local procedures.

GO TO NEXT PAGE

2-490