TM 5-3895-373-34

2.33

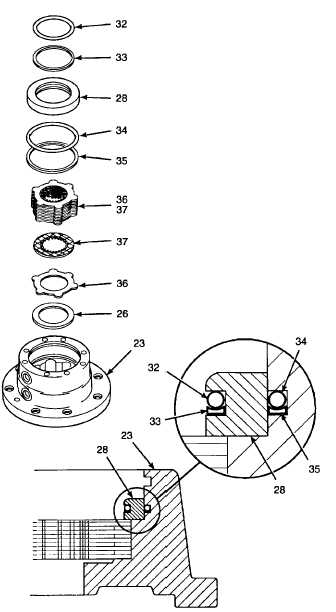

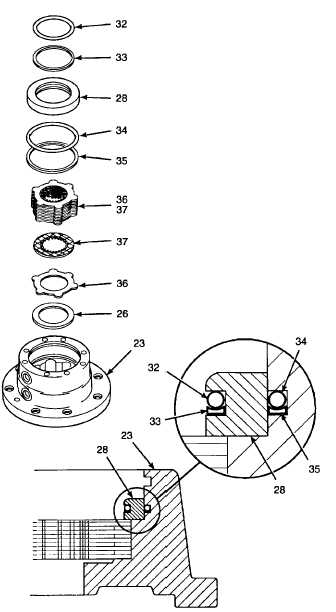

REPLACE/REPAIR SPEED REDUCTION GEARBOX - Continued.

E.

ASSEMBLE - Continued.

3.

ASSEMBLE BRAKE COMPONENTS.

a.

Install one thrust bearing (26), followed by one

steel disc brake (36), then one sintered disc

brake shoe (37) in brake housing (23). Repeat

installation of steel disc brake, then sintered disc

brake shoe until all disc brakes and shoes are

installed. Each sintered disc brake shoe must be

installed between two steel disc brakes.

O-rings,

seals,

ring

spacer,

and

cylindrical piston must be well lubricated

with petrolatum. Inadequate lubrication

may cause damage to o-ring or seal

during installation of ring spacer or

cylindrical piston.

NOTE

Refer to sectional view for proper

positioning of seals and o-rings.

O-rings may have to be stretched slightly

to fit tightly against outer diameter of

mating grooves.

NOTE

Plain seal (35) may not be used in all

applications.

b.

Lubricate o-rings (32 and 34) and plain seals (33

and 35) with petrolatum.

c.

Turn concave side of plain seal (35) up. Install

seal, concave side up, in bottom of lower

packing groove inside brake housing (23).

d.

Install o-ring (34) directly above installed plain

seal (35). Coat exposed surfaces of installed o-

ring and seal with petrolatum.

e.

Turn part number side of ring spacer (28) down.

Install plain seal (33), concave side up, in bottom

of packing groove in ring spacer.

SECTIONAL VIEW

f.

Install o-ring (32) directly above installed plain

seal 33). Coat exposed surfaces of installed o-

ring and seal with petrolatum.

g.

With part number side down, insert ring spacer

(28) in brake housing (23). Press ring spacer

squarely down until seated. Be careful not to

extrude o-ring (34) or plain seal (35).

GO TO NEXT PAGE

2-488