TM 5-3895-373-34

2.19

REPLACE/REPAIR FUEL INJECTION PUMP - Continued.

E.

ASSEMBLE - Continued.

NOTE

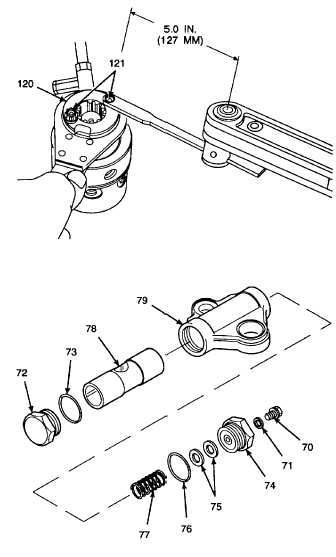

Torque wrench handle and adapter

handle must remain in a straight line

during tightening procedure.

h.

Hold governor hub (120) with a spanner

wrench from DPA tool kit.

i.

Use an adapter from DPA tool kit to tighten

drive screws (121). Holding tool handles in

a straight line, with center of adapter and

center of spanner wrench at a distance of

5.0 in. (127 mm). Tighten screws to 180 lb-

in (21 N•m).

j.

Partially loosen drive screws (121) one turn

and repeat tightening operation three times

to ensure torque is correct.

k.

Turn off nozzle testing unit.

l.

Disconnect pressure port adapter.

8.

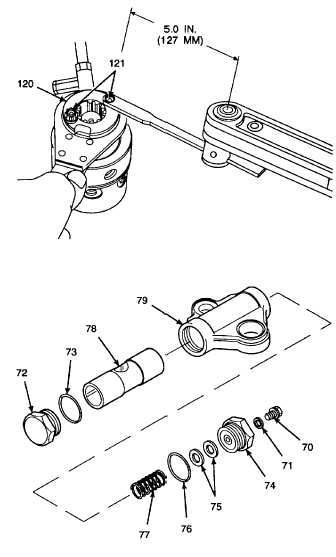

INSTALL PISTON, SPRING, SHIM, SPRING

CAP, AND HEX HEAD CAP SCREW INTO

AUTO ADVANCE HOUSING.

NOTE

Hollow end of piston must face

spring cap on housing.

a.

Install piston (78), with hollow end of piston

facing spring cap (74) and piston bore

aligned with bore in auto advance housing

(79).

b.

Lubricate preformed packings (76 and 73)

and flat washer (71) with clean calibrating

fluid.

Be careful not to damage preformed

packing when sliding over threads.

Sharp edges of thread can cut or

damage

preformed

packing.

Damaged

preformed

packing

will

cause

leakage

and

affect

performance.

c.

Install spring (77), shims (75), preformed

packing (76), and spring cap (74). Tighten

spring cap to 250 lb-in

d.

Install flat washer (71) and hex head cap

screw (70). Tighten cap screw to 40 lb-in

(5 N•m).

e.

Install preformed packing (73) and plug (72)

hand tight.

GO TO NEXT PAGE

2-274