TM 5-3895-373-34

C.

INSPECT - Continued.

d.

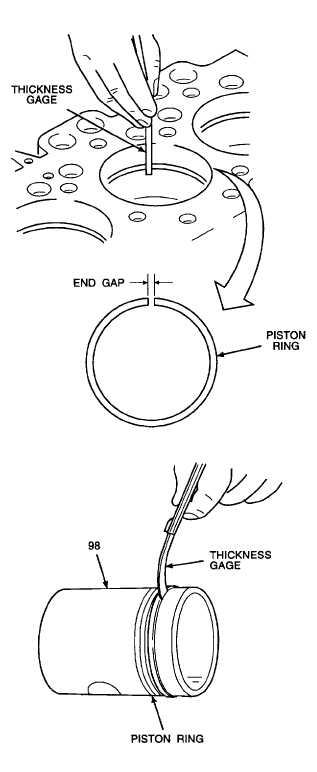

Insert new piston rings, one at a time, into

cylinder sleeves, about 1.0 in. (254 mm) down

inside cylinder sleeve.

e.

Use a thickness gage to measure piston ring

end gaps.

f.

For gap tolerances on each piston ring, refer to

the table below.

Piston

Ring

Minimum

Maximum

Ring

Type

Gap

Gap

Top

Compression

0.010 in.

0.022 in.

Number 1

(0,25 mm)

(0,55 mm)

Center

Compression

0.008 in.

0.022 in.

Number 2

(0,20 mm)

(0,55 mm)

Bottom

Scraper

0.010 in.

0.032 in.

Number 3

(0,25 mm)

(0,81 mm)

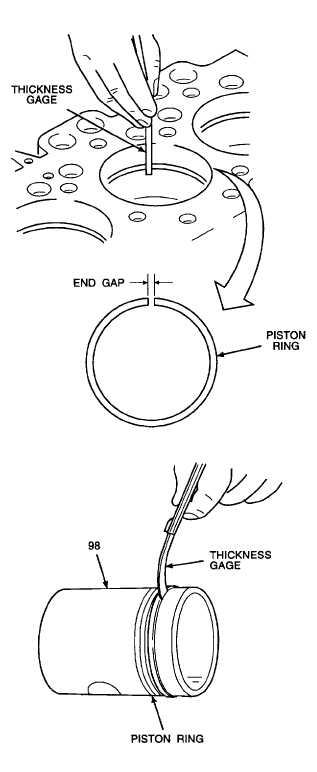

g.

Using piston ring expanding tool, fit new piston

rings into their respective grooves in piston

(98).

h.

Use a thickness gage to check fit of piston

rings in groove. Refer to table below.

Piston

Ring

Minimum

Maximum

Ring

Type

Fit

Fit

Top

Compression

0.0035 in.

0.0050 in.

Number 1

(0,088 mm)

(0,127 mm)

Center

Compression

0.0025 in.

0.0040 in.

Number 2

(0,063 mm)

(0,106 mm)

Bottom

Scraper

0.0020 in.

0.0032 in.

Number 3

(0,050 mm)

(0,081 mm)

i.

If clearance between ring and groove exceeds

maximum fit specifications, replace piston.

j.

Remove new piston rings from piston (98).

GO TO NEXT PAGE

2-177