TM 5-3895-373-34

2.76

REPAIR SCREED VIBRATION MOTOR - Continued

D.

ASSEMBLE - Continued.

2.

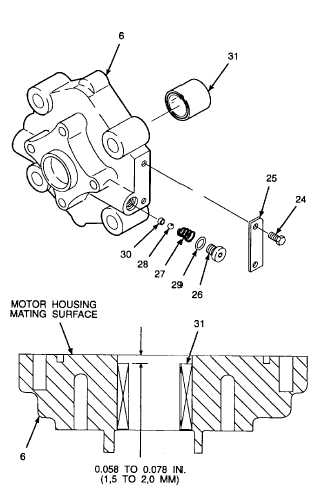

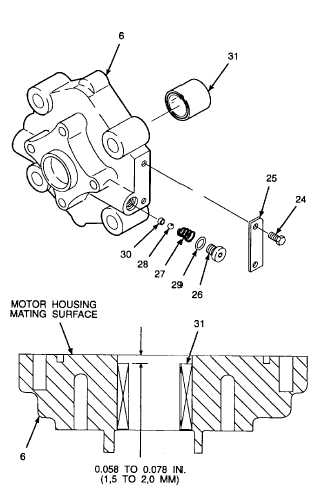

INSTALL NEEDLE BEARING AND CHECK

VALVE INTO MOTOR COVER.

a.

Use a hydraulic press and spacer from universal

puller kit and install needle bearing (31) into

motor cover (6). Use micrometer depth gage

and ensure that the clearance between the top

of the bearing and the motor body mating

surface of the motor cover is between 0.058 to

0.078 in. (1, 5 to 2, 0 mm). This is to ensure

that the bearing does not contact the retaining

ring.

b.

Use a hydraulic press and the valve seat

installation tool and press check valve seats’ (30)

into motor cover (6).

Hydraulic

oil

can

be

moderately

flammable and can be an irritant to

the

skin,

eyes,

and

respiratory

system. Avoid prolonged exposure.

Eye protection and rubber gloves

must be worn m. when working with

hydraulic oil.

Be careful not to damage preformed

packing when sliding over threads.

Sharp edges of thread can cut or

damage

preformed

packing.

Damaged

preformed

packing

will

cause

leakage

and

affect

performance.

c.

Lubricate preformed packings (29) with clean

hydraulic oil and install onto hex socket plugs

(26). Ensure that the packing is not damaged by

the threads of the plug.

d.

Install balls (28), springs (27), and hex socket

plugs (26) into motor cover (6).

e.

Install identification plate (25) and machine

screws (24) into motor cover (6).

GO TO NEXT PAGE

2-1080