TM 5-3895-373-34

A.

DISASSEMBLE - Continued.

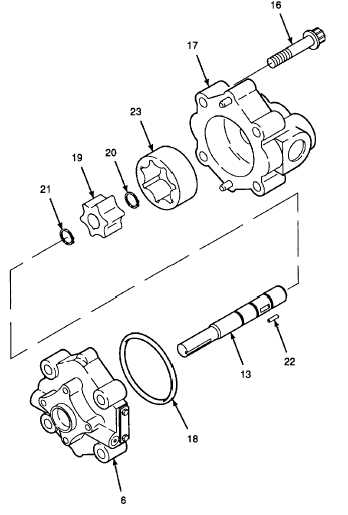

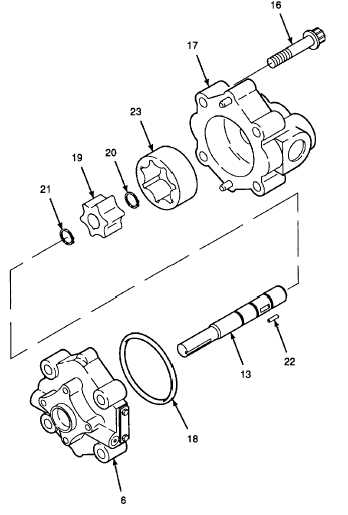

3.

REMOVE AND DISASSEMBLE MOTOR SHAFT.

Screed vibration motor body damage

can occur from clamping in a bench

vise. Use vise jaw caps between the

vise clamps and the motor body to

protect the aluminum motor body

when clamping. Failure to do so may

result in damage to the motor body.

a.

Place the screed vibration motor in a bench vise.

Protect the aluminum motor body from damage

by placing vise jaw caps between the vise

clamps and the motor.

b.

Remove motor body screws (16) from motor

body (17) and remove screed vibration motor

from the bench vise.

c.

Separate motor body (17) from motor cover (6)

and remove preformed packing (18). Discard

preformed packing.

d.

Slide motor shaft (13) and inner gerotor gear

(19) from motor cover (6) or motor body (17).

Use care when removing or installing

snap and retaining rings. Snap and

retaining

rings

are

under

spring

tension and can act as projectiles

when

released

and

could

cause

severe eye injury.

e

Use snap ring pliers and remove retaining rings

(20 and 21) from motor shaft (13).

f.

Remove drive pin (22) and inner gerotor gear

(19) from motor shaft (13).

g.

Remove outer gerotor gear (23) from gear

pocket in motor body (17).

GO TO NEXT PAGE

2-1075