TM 5-3895-373-34

2.76

REPAIR SCREED VIBRATION MOTOR - Continued

A.

DISASSEMBLE - Continued.

4.

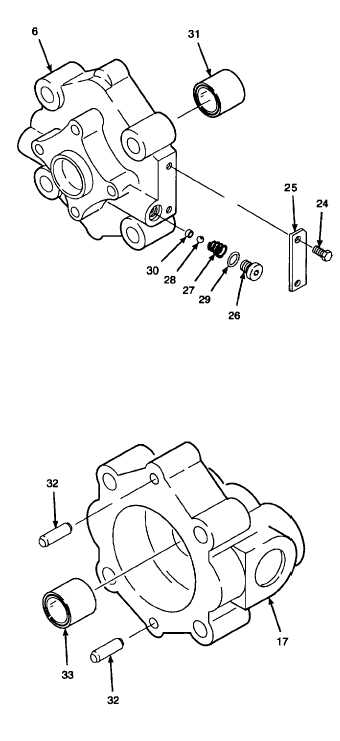

REMOVE CHECK VALVE AND NEEDLE BEARING

FROM MOTOR COVER.

a.

Remove machine screws (24) and identification

plate (25) from motor cover (6).

b.

Remove hex socket plugs (26), springs (27), and

balls (28) from motor cover (6).

c.

Remove preformed packings (29) from hex

socket plugs (26). If preformed packings are

damaged or worn, discard preformed packings

and hex socket plugs as a set.

d.

Inspect check valve seats (30) while still installed

for damage that would affect the seating of balls

(28). If no damage is found, do not remove.

e.

If damage is found to check valve seats (30),

use a #1 drill bit, size 0.228 in. (7, 75 mm) and a

portable electric drill, and drill out the check

valve seat.

NOTE

The needle bearing should only be

removed

if

obvious

damage

is

observed. Refer to step C.1 for

damage criteria.

f.

Use a hydraulic press and universal puller kit to

remove needle bearing (31) from motor cover

(6). Discard needle bearing.

5.

DISASSEMBLE MOTOR BODY.

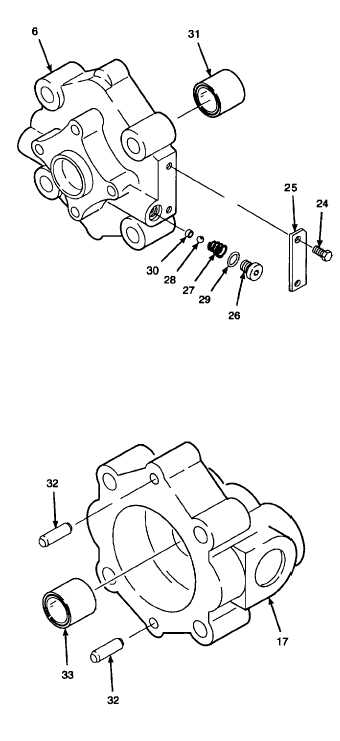

a.

Use a pair of pliers and remove dowel pins (32)

from motor body (17). Ensure not to damage

outer surface of dowel pins when removing.

NOTE

The needle bearing should only be

removed

if

obvious

damage

is

observed. Refer to step C.2 for

damage criteria.

b.

Use internal bearing puller from universal puller

kit and remove needle bearing (33) from motor

body (17). Discard needle bearing.

GO TO NEXT PAGE

2-1076