TM 5-3895-373-34

2.76

REPAIR SCREED VIBRATION MOTOR - Continued

C.

INSPECT.

1.

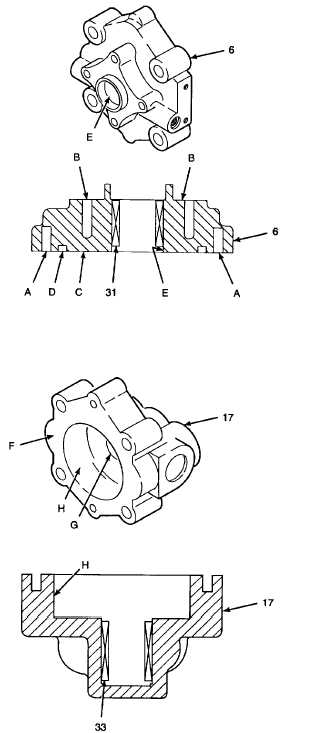

INSPECT MOTOR COVER AND COMPONENTS.

a.

Spin needle bearing (31) and inspect for bearing

surface wear and rough or impeded bearing

rotation. Replace the bearing if any damage is

found.

b

Inspect motor cover (6) threaded holes A and B

for damaged or stripped threads. Inspect mating

surface C and seal groove D for wear, cracks, or

damage that affect the seal of the screed

vibration motor.

c.

If needle bearing (31) has been removed,

inspect inner bearing surface E of motor cover

(6) for surface wear, cracks, or any damage that

would affect the proper operation of the bearing.

d.

If any damage is found to motor cover (6),

discard motor cover.

2.

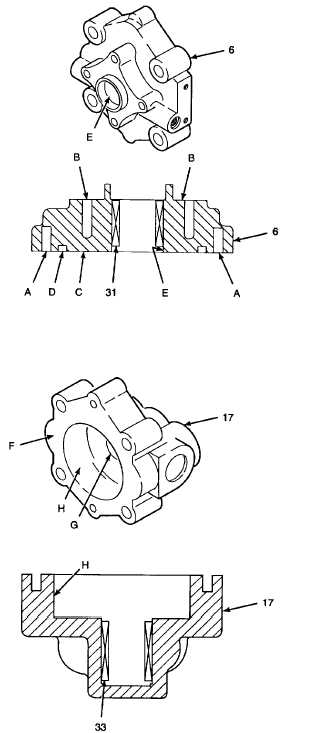

INSPECT MOTOR BODY AND COMPONENTS.

a.

Spin needle bearing (33) and inspect for bearing

surface wear and rough or impeded bearing

rotation. Replace the bearing if any damage is

found.

b.

Inspect motor body (17), sealing surface F, for

wear, cracks, or damage that would affect the

seal of the screed vibration motor.

c.

If needle bearing (33) has been removed,

inspect inner bearing, surface G, of motor body

(17) for surface wear, cracks, or any damage

that would affect the proper operation of the

bearing.

d.

Inspect gear pocket, surface H, on motor body

(17) for surface wear, cracks, or damage that

would affect the proper operation of the gerotor.

e.

If any damage is found to motor body (17),

discard motor body.

GO TO NEXT PAGE

2-1078