TM 5-3895-373-34

C.

INSPECT - Continued.

3.

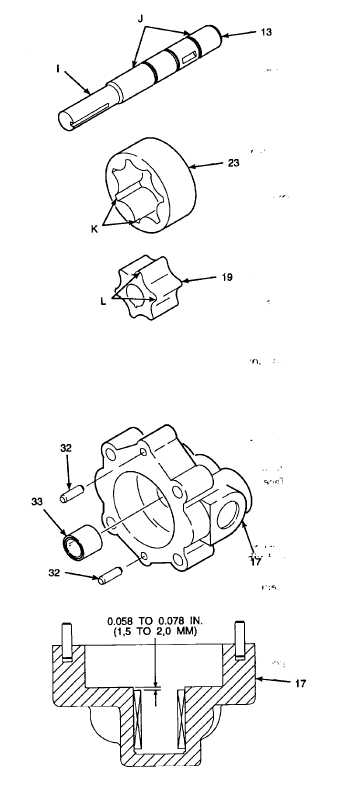

INSPECT MOTOR SHAFT, OUTER GEROTOR

GEAR, AND INNER GEROTOR GEAR.

a.

Inspect motor shaft (13), surfaces I and J, for

scoring, gouges, cracks, out-of-roundness or

shaft warping.

b.

Inspect outer gerotor gear (23) for chipped,

worn, or gouged gear, surfaces K. Inspect inner

gerotor gear (19) for excessively rounded,

chipped and worn drive gear lobes L. Replace

both outer gerotor and inner gerotor gears as a

set if any damage is found.

D.

ASSEMBLE.

1.

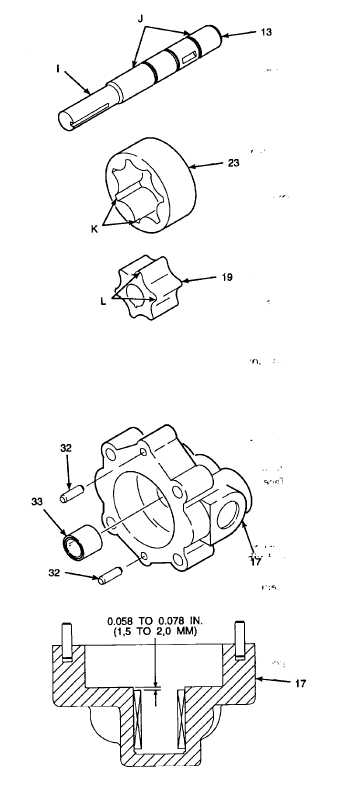

ASSEMBLE MOTOR BODY.

a.

Use a hydraulic press and spacers from

universal puller kit and install needle bearing (33)

into motor body (17). Use micrometer depth

gage and ensure that the clearance between the

top of the bearing and the motor body gear

pocket is between 0.058 to 0.078 in. (1, 5 to 2, 0

mm). This is to ensure that the bearing does not

contact the retaining rings.

b.

Use a plastic hammer and tap dowel pins (32)

into motor body (17).

GO TO NEXT PAGE

2-1079