TM 5-3895-373-20

2.24.3. SCREED REMOVAL AND INSTALLATION - Continued.

B.

INSTALL - Continued.

NOTE

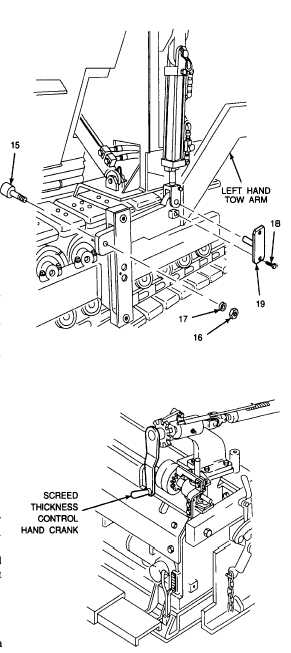

Installation procedure for left hand

and right hand tow point hardware is

the same. Left hand tow point

hardware is shown in this procedure.

2.

INSTALL TOW POINT HARDWARE.

Thread locking compound solvent

can cause eye damage. Wear safety

goggles/glasses when using. Avoid

contact with eyes. If solvent contacts

eyes,

flush

with

water

and

get

immediate medical attention.

a.

Clean threads of hex head cap screws (18) with

thread locking compound solvent. Wipe threads

dry with lint-free cloth.

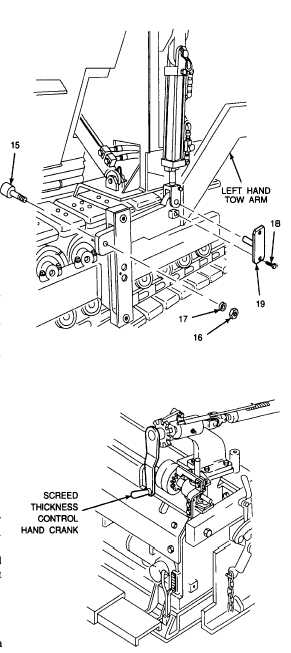

b.

With throttle control switch in IDLE position, jog

left hand tow point movement switch up or down

per TM 5-3895-373-10 to line up hole in tow

point cylinder clevis with hole in tow arm. If

further adjustment is required, adjust tow arm up

or down with screed thickness control hand

crank. Install tow point locking pin (19).

Thread locking compound can cause

eye

damage.

Wear

safety

goggles/glasses when using. Avoid

contact with eyes. If compound

contacts eyes, flush eyes with water

and get immediate medical attention.

c.

Apply thread locking compound to hex head cap

screw (18). Install and tighten cap screw to 37

lb-ft (50 N•m).

d.

Install roller (15), washer (17), and hex nut (16).

Hold head of roller with flat head screwdriver bit

and socket wrench. Tighten hex nut.

e.

Repeat steps b through d at right hand tow arm.

f.

Shut off engine and remove key from ignition

switch per TM 5-3895-373-10.

GO TO NEXT PAGE

2-462