TM 5-3895-373-20

2.24.3. SCREED REMOVAL AND INSTALLATION - Continued. ,.

A.

REMOVE - Continued.

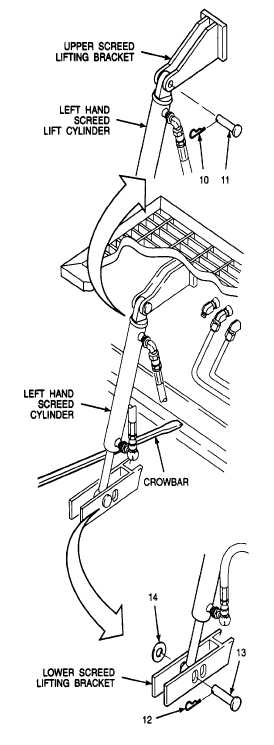

NOTE

Disconnection

procedure

for

left

hand and right hand screed lift

cylinders is the same. Left hand

screed lift cylinder is shown in this

procedure.

3.

DISCONNECT SCREED LIFT CYLINDERS.

a.

Check that screed vibrator, extension screed

control, and burner fuel pump switches are

turned to the OFF position at operator switch

panel and screed control panels per TM 5-3895-

373-10.

b.

Pull lock pins (10) from left hand and right hand

screed lift cylinders.

c.

Start up paving machine and place screed lift

switch in down, FLOAT position per TM 5-3895-

373-10.

d.

While another person uses crowbar to pry up on

cylinder tube of each screed lift cylinder, remove

clevis pins (11).

e.

Place screed lift switch in up, RAISE position

and partially retract cylinders. Leave cylinder

piston rods extended 6 to 8 in. (150 to 200 mm).

f.

Shut off engine and remove key from ignition

switch per TM 5-3895-373-10.

g.

Note which pin slot (front or back) is being used

in lower screed lifting bracket. While lifting up on

the screed lift cylinder have another person pull

lock pins (12), clevis pins (13), and flat washers

(14).

GO TO NEXT PAGE

2-458