TM 5-3895-373-20

A.

REMOVE - Continued.

h.

Use tie wraps to suspend screed lift cylinders

from grating of operator platform. Secure both

ends of each cylinder.

i.

Reinstall clevis pins (11 and 13), lock pins (10

and 12), and flat washer (14) in screed lifting

brackets.

4.

REMOVE TOW POINT HARDWARE.

NOTE

Removal procedure for left hand and

right hand tow point hardware is the

same. Left hand tow point hardware

is shown in this procedure. Tow

point cylinders may need to be raised

or lowered to access screwdriver slot

in roller (15) with screwdriver bit and

socket wrench.

a.

If required, start paving machine. Using tow

point control switches, raise or lower tow point

cylinders. Refer to TM 5-3895-373-10.

b.

At left hand tow arm, hold head of roller (15) with

flat head screwdriver bit and socket wrench.

Remove hex nut (16), washer (17), and roller.

c.

Remove hex head cap screw (18).

d.

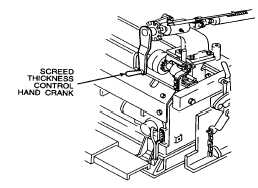

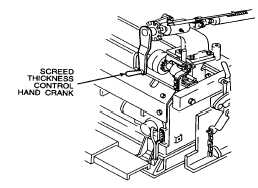

Using tow point control switches, raise or lower

tow point cylinders to free tow point locking pin

(19). Final adjustment may be made using

screed thickness control while removing tow

point locking pin. Refer to TM 53895-373-10.

Remove tow point locking pin.

e.

Repeat procedures in steps b, c, and d at right

hand tow arm.

f.

Shut down paving machine per TM 5-3895-373-

10.

GO TO NEXT PAGE

2-459